- Author Matthew Elmers elmers@military-review.com.

- Public 2023-12-16 21:49.

- Last modified 2025-01-24 09:17.

On January 31, 1932, at the Magnitogorsk Metallurgical Combine, through the heroic efforts of many thousands of workers: workers and engineers, the first blast furnace was put into operation. The launch of advanced metallurgical production in the Urals was a real technological and strategic breakthrough for the young Soviet country.

Magnetic has been dreamed of for a long time and used mercilessly

Details: https://regnum.ru/news/society/2068558.html Any use of materials is allowed only with a hyperlink to the IA REGNUM.

So, the first blast furnace was launched on January 31, 1932, but February 1, 1932 is considered the official birthday of the Magnitogorsk Iron and Steel Works - on this day, the blast furnace produced the first metal. The Magnitogorsk Iron and Steel Works first bore the name of Lenin, who took part in its creation by thought, then Stalin, who took part in deed. During perestroika, it became simply the Magnitogorsk Metallurgical Combine, but it remained the flagship of Russian metallurgy, which is not very easy to get a job for.

But back to the first blast furnace. It is well known that metallurgy in Russia was created not so much by prudent capitalists as by adventurers and romantics. And, oddly enough, it worked. So it happened with the plans to build a metallurgical plant in the South Urals near Magnitnaya Mountain, practically in an open field, because there was not a forest nearby, which was used to heat low-power blast furnaces even before the revolution, no other types of fuel. Even if you mine ore, how can you process it later?

Magnitka. Start of construction of Magnitogorsk. Start of construction

However, the reserve of Magnitnaya Mountain - half a billion tons of iron ore, partially coming to the surface - did not give rest to industrialists even before the revolution. The ores were very rich. The best samples contained up to 70% iron. And, of course, those who understood what results it would bring dreamed of being given the right to develop a field at Magnitnaya.

It should be noted that Magnitnaya Mountain is not a monolith, but a group of low "old" mountains, covering an area of about 25 square kilometers. These are the mountains - Atach, Dalnyaya, Uzyanka, Yezhovka, Berezovaya, which are located on the left bank of the Ural River.

In 1743, the Orenburg governor Neplyuev founded the fortress "Uyskaya line". According to some reports, it was intended to protect Magnitnaya from illegal mining of ore. The village of Magnitnaya soon appeared near the fortress. On May 6, 1774, Emelyan Pugachev tried to capture it. The battle with the tsarist troops turned out to be strange. During the day, the fortress fiercely resisted, and at night the troops went over to the side of the "Tsar-Liberator". And the village became a stronghold and base of the Pugachev army …

This is not to say that there was no attempt to develop ore at Magnitnaya before the Soviet era. The industrialists Ivan Borisovich Tverdyshev and his son-in-law Ivan Stepanovich Myasnikov were the first to receive permission to extract minerals and build factories in this place - on the Avzyan and Tirlyanka rivers. It happened on October 27, 1752. They built 15 factories in the South Urals (one of the first - Beletsky), which worked mainly serfs. Together with the civilian workers, their number amounted to 6 thousand people.

The cheap cost of serfs' labor became the basis of profits in these factories. According to some reports, a pood of ore harvested and piled at the foot of the mountain cost the breeders 0, 06 kopecks, and together with delivery to the plant - 2, 36-2, 56 kopecks. The ore was mined in the most primitive way - with a pick and a shovel. Working conditions were such that people died before they reached the age of 30, but profits still grew, as did the country's need for pig iron. However, in 1877, the enterprises became unprofitable and for the debts went to a joint-stock company, and, in fact, to the German-Belgian company Vogau and Co., which significantly modernized all technological processes and purchased new equipment. But the extraction was still carried out by the great-grandfather's methods - spontaneously, primitively and predatory.

Should we build a new plant? A revolutionary solution

Meanwhile, the rich Magnitka constantly attracted the attention of scientists. They investigated it both in the 18th and 19th centuries. And at the beginning of the twentieth century, when a government commission was sent there under the leadership of Dmitry Ivanovich Mendeleev. Only then they began to lay the correct ore sections, stopping the spontaneous mining of ore by the population.

Arrival of workers for the construction of Magniitka. 1929 Arrival of workers for the construction of Magniitka. 1929

Another commission - under the leadership of Vladimir Ivanovich Bauman (professor of the St. Petersburg Mining Institute and the creator of modern mine surveying) and Ivan Mikhailovich Bakhurin (developed the theory of interpretation of magnetic intelligence data and methods of magnetic microshooting for mine surveying purposes) - was sent to Magnitnaya in 1917-1918 and also appreciated its potential. Before the revolution, insignificant quantities of ore mined from Magnitnaya Mountain were transported to the Beloretsk plant for processing. Let us remind you that it was impossible to process it using the previous methods - with the help of charcoal - due to the lack of forests.

Meanwhile, coke has long been used in the ferrous metallurgy of Ukraine. And this method was approved by the same Dmitry Ivanovich Mendeleev, who believed that it was simply necessary to build large blast furnaces in the Urals and Siberia. But there have never been any coal deposits near Magnitnaya. The nearest was in the Kuznetsk coal basin, that is, in the Kuzbass. To take coal from there, and get metal in return? It's insanely expensive and unprofitable! This "pendulum" was considered an economic utopia. It is much cheaper to develop metallurgy in Ukraine - in Donbass and Krivoy Rog!

In his article "Stalin's Industrialization" Mikhail Kiryukhin writes: "The talented mining engineer P. I. Palchinsky opposed the Magnitka project … In his opinion, the choice of a site for the construction of a metallurgical plant should have been based on many factors, of which the proximity to the deposit decisively cannot be in charge. Palchinsky cited as an example the experience of the United States, where metallurgical plants are located in places with a sufficient amount of labor resources and where it is relatively cheap - along the river (Detroit, Cleveland and the actual prototype of Magnitka - a factory in Gary, Indiana) or along the existing railway - to deliver the necessary resources (and Pittsburgh so generally stands on a huge coal deposit, but not iron). He encouraged the engineers involved in the development of such a large plant to choose between possible alternatives and take into account the cost of logistics; demanded additional research of deposits, insisted that meeting the most basic needs of workers (housing, food, quality of life) is not a question of the ethics of building communism, but a strictly necessary condition for the qualitative growth of production. Palchinsky called, argued, demanded, explained, insisted, justified - and was shot without trial. " Palchinsky became one of the first in the list of victims of the construction of Magnitka.

However, the idea of building the MMK also had an unexpectedly strong supporter - Vladimir Ilyich Lenin, who paid special attention to the rich subsoil of the Urals and highly appreciated the potential of Siberia and the South Urals in terms of mining. He also believed that the expensive transportation of coal to Magnitnaya would fully pay off with the high content of iron ore in the rock and the low cost of its extraction. After all, she also had exits to the surface.

Of course, we need a transport infrastructure, a new railway, new technologies. But here you can turn to foreign experience. The main thing is that after the victory of the October Revolution, the problem could be solved on a national scale. In addition, it will not hurt to use the enthusiasm of the proletariat, and how cheap the labor force will be.

A commission was created that was supposed to develop a plan for the transfer of heavy industry beyond the Urals, as well as calculate the possibilities of a single economic complex connecting the Kuzbass and the South Urals. And then this idea had many opponents, who considered it ruinous for the country. However, the commission produced encouraging results.

“In November 1926, the Presidium of the Ural Regional Economic Council approved the construction site for a new metallurgical plant - a site near Magnitnaya Mountain. On March 2, 1929, Vitaly Hasselblat was appointed chief engineer of Magnitostroi, who immediately went to the United States as part of a group of Soviet specialists, - the RNNS information resource writes, referring to the Expert magazine, in the article "The War That Could Not Be". - The trip plans included an order for both construction projects and the American industrial equipment necessary for the plant. The main result of the trip was the conclusion on May 13, 1929 of an agreement between the Vostokstal association and Arthur McKee from Cleveland for the design of the Magnitogorsk Metallurgical Plant (a little later a contract was concluded with the German company Demag for the design of the rolling shop of this plant)."

McKee engineers developed the general layout of the plant, along with engineers from the Ural Institute Gipromez. According to the calculations of the Americans, the furnace should have been started up in 1934.

Another "strong business executive" Lazar Moiseevich Maryasin became the head of the construction of the by-product coke plant, whose products were so necessary for the successful operation of the blast furnace. His work was assessed in different ways, there were claims both to the organization of construction and the life of workers, and to the violation of certain technological conditions. However, the country's leadership was initially satisfied with the results, and in 1933-36 he became the head of the construction of the Uralvagonzavod.

46 design organizations, 158 factories, 49 railways, 108 universities took part in the construction of MMK. It was Russian design engineers who made most of the technical documentation for MMK.

However, the process needed a leader who could combine all the efforts of the performers and direct them in the right direction. In 1931, they became a strong business executive who was well versed in metallurgy and already had experience in managing specialized factories, Yakov Semenovich Gugel (born in 1895 - shot in 1937), who had previously had extensive experience in managing the metallurgical industry.

Magnitka. Construction of Magnitka. Construction

He was a man of a decisive character, so he immediately began to remove unnecessary things and put things in order at the construction site, which was carried out at an amateurish level - with the squandering of building materials, equipment and the chaotic distribution of labor among objects. He planned the creation of separate shops - blast furnace, open-hearth and rolling. Now both builders and designers clearly understood their tasks. The stove without a reservoir was erected in 74 days.

On June 30, 1929, the construction of the Kartaly - Magnitogorsk railway line was completed, workers began to arrive at the construction site.

On May 15, 1931, the mine was commissioned.

On July 1, 1930, the solemn laying of the first blast furnace was carried out. The ceremony was attended by 14 thousand workers.

On October 9, blast furnace # 1 was put to dry.

On January 31, 1932, at 11:15 am, the furnace was started up (blown out), although American scientists believed that it was technologically impossible to do this in thirty-degree frost.

On February 1, 1932, at 21:30, the furnace produced the first pig iron.

To maintain the feeling of “revolutionary pride”, a dozen iron plates with the image of Lenin and the inscription “As a sign of your active participation in the construction of the first stage of the Magnitogorsk Metallurgical Combine, the plant management presents you with a commemorative plaque cast from the first smelting of the blast furnace. No. 1 - February 1, 1932.

What were the "leading articles" silent about …

Back in 1932, Joseph Vissarionovich Stalin was already in power in the USSR, insisting on a tight deadline for launching the furnace. Neither the management of MMK nor Ordzhonikidze dared to disobey him, despite the just protests of the Americans.

The furnace was started up, reported, but the pipes that were underground burst from the temperature difference. A fragment of masonry flew out of one section of the furnace. From there, hot gases escaped, accompanying the steelmaking process. According to the historians of Magnitogorsk, people made fires to warm the earth, get to the pipes and patch them up. At the same time, not a single person got sick. Well, the situation itself was the reason for the termination of the contract with McKee. Very handy, since the Soviet leadership was running out of currency.

On October 1, 1936, by order No. 1425 of the People's Commissariat of Heavy Industry, the construction of the MMK was transferred to the contracting method, for which the construction and installation trust "Magnetostroy" was organized under the jurisdiction of the GUMP NKTP. Konstantin Dmitrievich Valerius was appointed as the manager. It has become a tradition of the trust to hand over objects on a turnkey basis.

The haste in launching blast furnace No. 1 of the MMN was clearly dictated by the strategic interests of the USSR. It was very unsettled in Europe, and no one ruled out the possibility of war. From a military point of view, to place a ferrous metallurgy complex beyond the Urals was a very important decision to strengthen the country's defense capability. Within a month after the start of the war, he gave the country armored steel. For the Urals, metallurgical plants were evacuated, which were able to continue their work on the basis of MMK. Steelworkers toiled for defense day and night.

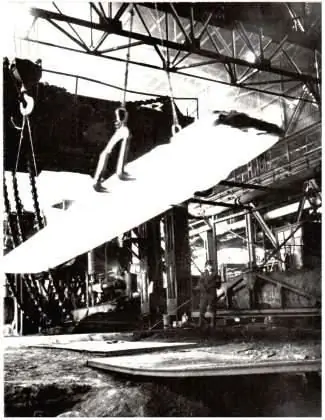

The first armor plate produced on blooming. July 1941 First blooming armor plate. July 1941

Since 1937, the heroic history of MMK has turned its dark side to the managers of the plant's construction. Let's start with Yakov Gugel, who was born in Belarus, who established Soviet power in Odessa, who fought with the White army in Bessarabia, who studied by fits and starts at the Institute of Technology and became one of the prominent leaders in metallurgy. In March 1935, Yakov Gugel was awarded the Order of Lenin for his services in the construction of two giants of the metallurgical industry of the first five-year plans - Magnitka and Azovstal.

Historian Lev Yarutsky wrote about him: “For the first time he was promoted to the post of independent production commander in Taganrog - at the age of 26 he became the director of a boiler plant. Then there were command positions at the Yuzovsky and Konstantinovsky metallurgical plants … Gugel immortalized his name by leading the construction of metallurgical giants of world importance. But besides Magnitka and Azovstal, he built another plant - the Mariupol Novotrubny named after V. V. Kuibyshev. However, this construction, and the fact that he saved the former Providence from dismantling and achieved its reconstruction, and that he raised the Ilyich plant to a height, all this is a “trifle” in comparison with the Magnitogorsk and Azovstal epics”.

However, on August 19, 1937, the operative of the 4th department of the UGB UNKVD of the Donetsk region, senior sergeant of state security Trofimenko, issued an order to arrest Gugel, which was sanctioned by the regional prosecutor. Soon Gugel recognized himself as a member of the Trotskyist organization organized in the Donbass, which was allegedly headed by Ordzhonikidze's favorite Georgy Gvakharia, who was appointed director of the Makeyevka Metallurgical Plant after he completely broke with Trotsky.

Gugel, according to Yarutsky, really did not approve of the actions of the Soviet government in everything, especially the voluntarism of Soviet officials in organizing production. On October 14, 1937, he was shot.

“When, according to the statement of Tatyana Ivanovna Gugel, the widow of Yakov Semenovich, who had served eight years in camps and prisons as“a member of the family of a traitor to the Motherland,”the assistant to the Military Prosecutor of the Kiev Military District for special affairs of the Stalin region, the captain of director of "Azovstal" and obtained absolutely irrefutable evidence of his innocence, - writes Yarutsky, - but, nevertheless, he came to the conclusion (and it was already after the XX Congress) that Tatyana Ivanovna's statement about the rehabilitation of her husband should be dismissed, Gugel was shot a second time. And only when all the "accomplices" of Gugel - Gvakharia, Sarkisov and others - received full rehabilitation (posthumous, of course) and a completely absurd situation arose, did they finally have mercy on Yakov Semenovich."

In the spring of 1936, the NKVD fabricated the case "On the activities of the sabotage Trotskyist organization at Uralvagonstroy, Uralvagonzavod", during which about two thousand people were arrested, including the heads of construction and the plant. Among them - Lazar Maryasin (1937), head of the Magnitostroy trust - engineer Konstantin Dmitrievich Valerius - a native of Zlatoust, headed the reconstruction of the Zlatoust metallurgical plant.

Sign “To the builder of the giant. Magnetostroy ". USSR, Leningrad, 1931 Sign “To the builder of a giant. Magnetostroy ". USSR, Leningrad, 1931

Blast Furnace No. 1 was completely renovated in the late 1990s. After the reconstruction, its volume increased to 1,370 cubic meters, the productivity reached 1.2 million tons per year. In December 2009, the furnace underwent a major overhaul and at the end of December 2009 again reached full capacity.