- Author Matthew Elmers elmers@military-review.com.

- Public 2023-12-16 21:49.

- Last modified 2025-01-24 09:17.

We paid a lot of attention to the history of the development of mortars. Whatever one may say, but today this type of weapon is one of the most deadly. Not potentially deadly, like nuclear weapons, for example, but really deadly. It is no exaggeration to say that mortar fire takes away someone's life or lives every day.

Finishing with this material about conventional mortars and moving on to reactive ones, we cannot but tell and show the best. Mortar.

Our hero really inspires respect and fear with his own power to everyone who has seen the results of his work at least once. A mortar that is capable of destroying almost any fortification. A mortar that can fire high-explosive, cluster, guided, incendiary, neutron and nuclear mines.

Even, quite possibly, some other ammunition unknown to us.

Today we will talk about a beautiful spring flower that men give their loved ones in spring. On March 8th.

We are talking about a tulip. More precisely, about "Tulip". About the self-propelled mortar of the Artillery of the Reserve of the Supreme High Command 2S4 "Tulip", caliber 240 mm. Designed to destroy fortified buildings, fortifications, accumulations of enemy personnel and armored vehicles, as well as the destruction of objects that, due to their high security, cannot be destroyed by artillery of a smaller caliber.

When you see a crater with a diameter of 10 meters and a depth of almost 6 meters, you really understand that this is a Weapon! And this is not some kind of special ammunition. This is a common mine. And an approximate view of a funnel appears in the head when working with special mines … And the results of this work for the enemy …

Where did this weapon miracle come from? And it appeared from the logic of the development of the Red Army back in 1938! It was then that a promising program for the introduction of mortars in the Red Army was adopted. From the rifle company to the High Command Reserve.

The difficulty of working on the RGK mortar was that the large (240-mm) caliber required completely new solutions even in such seemingly obvious things as aiming the mortar at the target, or loading. Agree, a 16-kilogram mine for a 120-mm mortar can be loaded in the traditional way. And a 130-kilogram mine of 240 mm? Yes, to a height of more than 5 meters?

There was one more difficulty. Purely practical. The war required the prompt production of not large caliber mortars, but battalion and regimental level mortars. 82 mm vs 120 mm. This is precisely the task that Headquarters set for the designers. A problem that has been successfully solved. What we wrote about in previous articles. And it was solved in many ways by the brilliant Soviet designer Boris Shavyrin.

For five years, our designers have been trying to create a super-powerful mortar. By 1943, two prototypes of 240 mm mortars were even created. But on tests, these mortars were not suitable for use. To put it bluntly, the mortar tests "failed" completely.

And then the design and creation of a 240-mm mortar was entrusted to Boris Shavyrin. By this time, he was the head of the Kolomna Special Design Bureau for Smoothbore Artillery (SKB GA). The famous designer abandoned the already used schemes and started working practically from scratch. Imagine, work began in January 1944, and in the same year, factory tests of a new mortar began!

After the end of the war, the country's leadership began to believe that there was no urgent need for a 240-mm mortar, and the work was stopped. But in 1947 they returned to the topic. Shavyrin's mortar was sent for state tests. In 1950, this mortar was put into service under the name M-240.

Unfortunately, the production of this mortar was stopped in 1958. The reason is the same as for other representatives of barrel artillery. The then head of state, N. Khrushchev, considered that such weapons were futile, and the future was in missiles. A total of 329 mortars were fired at factory # 75 in the town of Yurga, Kemerovo Region.

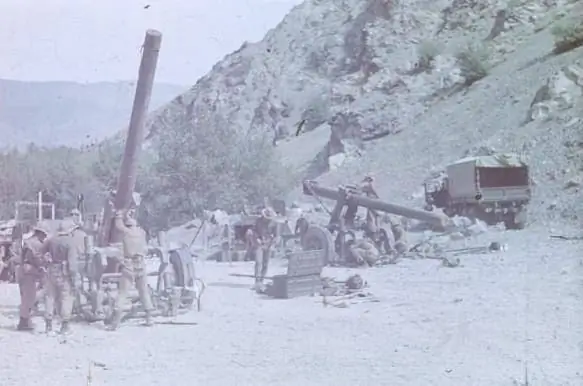

But the M-240 found its own war. 1985 in Afghanistan. In the fall of 1984, the howitzer battery of the 1074th artillery regiment of the 108th motorized rifle division was rearmed with 4 M-240 mortars. The soldiers and officers of the battery were retrained in the Union. The first combat use of the M-240 and the Smelchak mine was in the Charikar Valley area. Later, the M-240s were in the Panjshir gorge, the spirits of Akhmat Shah Masud were beaten. The effectiveness of the mortar was amazing. One, maximum two shots to destroy the target!

What is the M-240 like? It is imperative to consider this mortar carefully. The fact is that it is the modification of this mortar under the designation 2B8 that makes up the artillery part of our "spring flower" - "Tulip".

The 240 mm M-240 mortar is a rigid structure (without recoil devices) on a wheeled carriage. It consists of the following parts: a barrel with a bolt, a frame with a shock absorber, a machine with guidance mechanisms, a balancing mechanism, an arrow with a mechanism for transferring a mortar from a traveling position to a combat position and vice versa, a base plate, a kingpin and sighting devices, The barrel has the form of a smooth-walled pipe, fixed in trunnion clips. Thanks to this, it has the ability to swing on the trunnions to bring it into the loading position.

Mortar with breech-loading loading system. When loading, the mortar barrel "breaks". A breech serves to close the barrel and transfer the recoil force to the base plate. Its tapered part ends with a ball heel, which connects the breech with the base plate bowl.

The machine consists of two frames (upper and lower) of stamped-welded structure, hingedly connected to each other. The rotary screw mechanism allows horizontal guidance without moving the wheels. Since the recoil force is quite significant, and the mortar has no anti-recoil devices, shooting at elevation angles of more than 45 ° is allowed only from solid ground and after several "shrinking" shots.

The lifting mechanism is screw type. Balancing mechanism - spring, located on the right side of the machine. The lower frame is assembled on the combat axle of a non-detachable wheel drive.

The suspension of the wheels is spring-loaded. The wheels themselves are of the YATB-4 trolleybus type, with a sponge filler. Towing of the M-240 is normally carried out by the AT-L tracked tractor, but other tractors, as well as the Ural and KamAZ trucks, can also be used.

For the delivery of mines to the firing position, a special single-axle cart was included in the mortar kit. Loading the mortar required a number of manipulations:

- the trunk is brought to a horizontal position;

- after opening the shutter, a tray is hung on the semiaxis of the shutter wedge;

- five people of the calculation manually lift the mine from the cart, put it on the tray and send it into the barrel;

- the tray is removed, then the barrel is lowered into the breech to fire a shot.

The main performance characteristics of the mortar:

Weight, kg

in combat position: 3610

stowed: 4230

Dimensions:

length, mm: 6510

barrel length, mm: 5340

width, mm: 2430

height, mm: 2210

Crew, people: 11

Elevation angle, degree: + 45 …. + 80

Angle of rotation, hail

at elevation 45: 16, 5

at elevation 80: 78

Rate of fire, rds / min: 1

Firing range, m:

for Ф864: 800-9650

for 3F2: 19690

But how did the "Tulip" appear? Believe it or not, but the fault of the appearance of this handsome man was … the Americans! More precisely, the use by the Americans of their SPGs in Vietnam. Unlike us, the Americans understood very well that a global war was possible purely theoretically. But regional wars are real. Therefore, they developed their own self-propelled guns. And Vietnam has become the proving ground where these machines have shown their effectiveness and necessity.

The fleet of Soviet cars of this class looked very pale against the western background. ACS during the Great Patriotic War were really not comparable with new machines. Even the ones that were on the list of the best. ISU-152 or SAU-100 by that time were already inferior to American systems in many respects. And we, according to the old Russian tradition, "rushed to catch up" with the West.

In July 1967, a decree was issued by the Central Committee of the CPSU and the Council of Ministers of the USSR on the development of new self-propelled artillery systems for the Soviet army. The complexes were supposed to include not only the self-propelled guns themselves, but the KShM. Several factories were obliged to develop and submit new systems for state tests at once.

It was in this program that the self-propelled heavy mortar "got". The development of these weapons was entrusted to the Ural Transport Engineering Plant in Sverdlovsk. But, realizing that Uraltransmash could not completely solve the task on its own, the development of the artillery unit of the mortar was entrusted to the Special Design Bureau of the Perm Engineering Plant, which specialized in artillery systems.

Thus, "Tulip" has two "dads" at once. The chief designer of the chassis, G. S. Efimov, and the chief designer of the 2B8 mortar, Yu. N. Kalachnikov.

Georgy Sergeevich Efimov

Yuri Nikolaevich Kalachnikov

First, about the chassis. The chassis developed for the Krug 2K11 air defense missile system in 1955-56 was taken as a basis. However, already during the design process, it turned out that the chassis for a heavy mortar was "rather weak". Starting with engine power (400 hp) and ending with the very structure of the chassis.

As a result, no more than 20% of components and mechanisms remained from the "original" chassis in the final version. The rest were redesigned for the specific requirements of the Tulip and the Akatsia howitzer, which the plant was working on in parallel.

Installed a V-59U engine with a capacity of 520 liters. sec., which provided a speed of up to 63 km / h and a cruising range of 500 km.

The machine body was welded. With protection against armor-piercing bullets of caliber 7, 62 mm and shrapnel. A bulldozer knife was installed in front to equip the position.

Functionally, the body is divided into three parts.

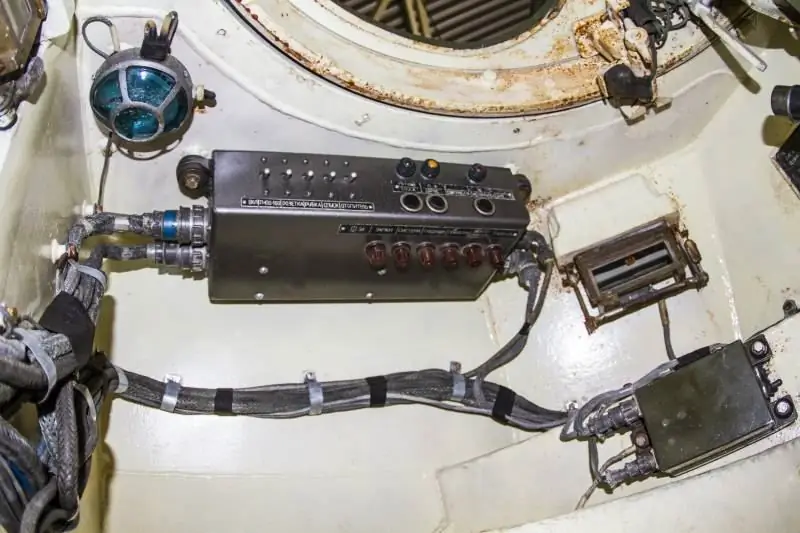

The control compartment is traditional for armored vehicles, to the left in front of the center of the hull. The engine compartment is on the right. The middle and aft parts of the hull are given to the fighting compartment.

In the center there is ammunition in a mechanized drum-type ammunition rack for 20 minutes and a mine feed mechanism.

In the middle part there is a mine supply hatch when loading. On the sides there are crew landing hatches. The mortar itself is attached to the rear of the hull.

The 2B8 mortar itself is not particularly different from the M-240. With the exception of the use of hydraulics which has become possible in the "machine version". Now vertical guidance is provided by means of a hydraulic mechanism, horizontal - manual.

The hydraulics also provides the transfer of the mortar from the traveling position to the combat position and vice versa, bringing the barrel to the line for discharging the mine, opening the bolt, feeding the mine from the mechanized ammunition rack to the rammer guides (located on top of the vehicle body), loading the mortar, closing the bolt and lowering the barrel into the breech.

It should be noted that the birth of "Tulip" was difficult. In factory tests, the first three prototypes showed quite good results. But on state trials in 1969, an incident occurred during the production of shots.

The first experimental sample at the "Rzhevka" training ground withstood only two shots. The fastening of the base plate, which rigidly connected it to the body of the machine, burst. A dynamic wave crumpled the fuel tanks into an accordion. I had to urgently change the design of the mount.

This did not prevent the adoption of the 240-mm self-propelled mortar of the RVK 2S4 "Tulip" artillery in 1971. And since 1972, the company has received an order for the production of the first 4 machines. In total, until 1988, when production ceased, about 588 Tulips were produced. We use the word "approximately" on purpose, since the amount varies somewhat from one source to another.

Speaking of "Tulip", one cannot ignore the topic of the ammunition used by the complex. Naturally, such weapons could not be used only for firing conventional, classic, ammunition. Talking about the M-240, we mentioned the weight of a conventional mine for this mortar. Just over 130 kilograms. But the firing range of such and mines is less than 10 kilometers.

A special active-reactive mine 3F2 was developed for the Tulip. Rocket-powered ammunition! This naturally dramatically increased the weight and length of the mine. The weight has increased to 228 kg! And, accordingly, the number of mines in the ammunition rack has decreased. Up to 10 pieces. But the range! More than 19 kilometers!

Mina 3F2

There are also "flower surprises". Nuclear mine 3B4 and its reactive version (like 3F2) 3B11, with a range of 18 kilometers. And "in the storeroom" there is also "Saida", equipped with napalm and burning everything around it on an area of 7850 sq. meters. There is also "Nerpa", a 3OF16 cluster mine with high-explosive fragmentation elements. There are Tar and Fata neutron shells.

Nuclear mine 3B4

But, in our opinion, the most interesting for consideration is the 3VF "Smelchak" adjustable mine. The same one that was used in Afghanistan by the gunners 1074 AP 108 MSD.

Mina 3F5 "Brave"

The name "adjustable mine" refers only to the ammunition itself. It is more correct to talk about the 1K113 guided weapons complex, which was put into service in 1983. And the complex, in addition to the mine, also includes a laser rangefinder-target designator 1D15 or 1D20.

For accurate shooting, it is enough to set the target designator at a distance of 200 to 5000 meters. Without going into technical nuances, the designator works for 0, 1-0, 3 seconds. This is enough to correct the mine. Even on difficult targets, the "highlight" lasts no more than 3 seconds. At the same time, the probability of a mine hitting a circle with a diameter of 2-3 meters is 80-90%. And at the very beginning of the article, we described the impressions of the crater after the explosion of an ordinary mine from the "Tulip".

Today it is difficult to see the "Tulip" in parts and formations. Most of these weapons are in conservation. But sometimes, quite unexpectedly, "Tulips" "show up". How it happened, for example, in the Donbass.

On July 6, 2014, the militia reported on the use of "Tulips" by the Armed Forces of Ukraine in the villages of Cherevkovka and Semenovka. Video recordings of these attacks can still be found on the Internet. And, as often happens in Ukraine, on August 15, DPR militias under the command of Bezler, while carrying out a raid into the rear of the Armed Forces of Ukraine, captured several artillery installations, including the "Tulip".

Soon the militia used this mortar. Probably, many remember the screams from Kiev about the supply of prohibited weapons from Russia. And the statement of the Minister of Defense of Ukraine about the tests of the Tulip in the east of the country … Galatey then explained the departure from the airport by the appearance of the Tulip there.

Finishing the story about the most powerful mortar currently existing in the world, I would like to express my admiration for the designers, engineers, technicians, workers who were able to create such weapons.

And the life of the 2C4 "Tulip" is not over. And it won't end for a long time. Since last year, those mortars that are in service have begun to be modernized. And this is the best indicator of the need for this weapon today and tomorrow …