- Author Matthew Elmers elmers@military-review.com.

- Public 2024-01-11 04:35.

- Last modified 2025-01-24 09:17.

Trials and the beginning of the series.

In September 1950, after fine-tuning and maintenance, tests were organized by the mileage of two DAZ-485. For comparison, we took the American prototype with us.

First, we passed the trial distance: Dnepropetrovsk - Zaporozhye and in the opposite direction with long swims along the Dnieper. From 23 to 25 September the next race: Dnepropetrovsk - Zhdanov (modern Mariupol) - Melitopol - Nikopol - Dnepropetrovsk. And from 26 to 30 September - from Odessa through Nikolaev with the crossing of the Bug. During the next exit to the shore with silt, one of the machines needed a winch. It was here that the possibility of issuing a cable to the front came in handy, which was not at the GMC - 353.

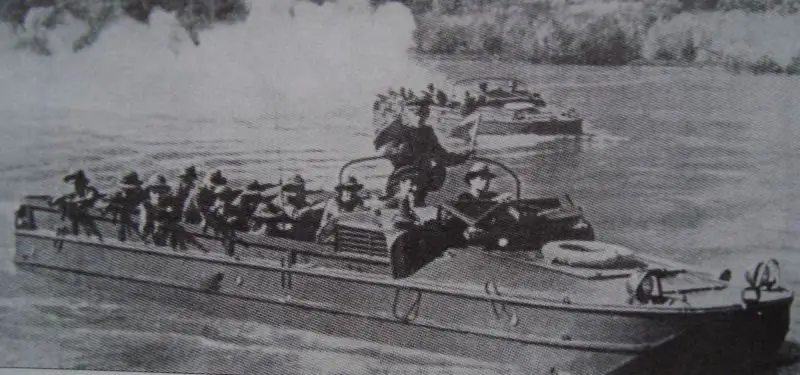

A group of testers on the Dnieper near Zaporozhye, 1950

In October 1950, a large run was carried out (which was counted as State tests) through the Crimea and the Caucasus: Kakhovka - Evpatoria - Yalta - Feodosia - Kerch - Taman - Anapa - Temryuk and back (about 6 thousand km). The Kerch Strait, then not yet completely cleared of mines and sunken ships, was forced by swimming. In the Kuban, they moved on soil sodden from rain, where no other transport could pass. We did long-term swims in the fast Kuban, including at night (with headlights) and against the current. On the way back we went to the Kerch Strait in a strong storm. It was forbidden to cross the strait in such weather. But the designers, headed by V. Grachev, who at such dangerous moments got behind the wheel himself, covering the top of the car with a tarpaulin, risked to swim across the 4-km strait. According to eyewitnesses, the representative of the Ministry of Defense grabbed his head - he should be answered! But V. Grachev only smiled at this - he believed in his car. And she did not disappoint: it went out well with its nose on the wave, the system perfectly coped with pumping out water that penetrated into the holds, all the units worked without interruption.

DAZ-485 on the Crimean land. October 1950

On the Crimean serpentines. In the background, an American amphibious vehicle GMC - 353

On the roads of Crimea

Caucasus, October 1950

The next interdepartmental tests of two vehicles were carried out in the spring of 1951 in the Leningrad Military District in the Yukholonmyaki area near Vyborg, on the Vuoksa River and neighboring lakes, which had sandy shores. The tests once again confirmed the correctness of the basic engineering solutions. The car turned out to be quite strong, mobile, easy to control, had a smooth ride and unprecedented cross-country ability. According to this indicator, he had no equal among wheeled vehicles in the whole world, and was practically not inferior to tracked models. Due to the successful choice of transmission, suspension, tires, the average speed on all types of roads at that time was relatively high - up to 30 km / h, and on difficult terrain - 10 km / h. The navigability was also good. A powerful three-bladed propeller, located in a deep tunnel, provided a high speed for amphibians of this class on the water - up to 10, 5 km / h, as well as confident swimming against the current.

Passage of the machine on swampy and soft soils

The amphibian's own weight was 7250 kg with a carrying capacity on land of 2500 kg, and on water - 3500 kg. At the same time, the so-called "vehicle weight coefficient", that is, the ratio of carrying capacity to its own weight on land was 0.34, and on water - 0.48. These data were not bad, but not ideal, which was due to a certain degree of imperfection design of certain components and assemblies.

On water, the minimum circulation (turning) diameter when driving at maximum speed and using the front wheels and a water rudder for turning was 15 m.

To pump out water from the body, the car was equipped with two pumps with a production capacity of up to 450 l / min. There was also a manual sump pump on the car, but with little power. Fuel consumption per 100 km on the highway was 47 liters, on water at a speed of 10 km / h - 30 liters.

Certain shortcomings were also discovered during tests: in some operating modes - going ashore with maximum load - the engine overheated (later an additional water heat exchanger was introduced), there were breakdowns of the clutch and propeller shafts (then they were strengthened), in some cases there was a shortage engine power (but there was no other then).

Front view of the DAZ-485. The guide bracket for the winch is clearly visible on the bow

Through the water hazard

After these tests in April 1951, the creators of DAZ-485 (head of the corps bureau B. Komarovsky, chief engineer of the plant G. Grigoriev, lieutenant colonel G. Safronov (from the Engineering Committee of the Soviet Army), innovator I. Tkhor and chief designer V. Grachev) received the Stalin Prize. The plant began preparations for the production of a small series of GAZ-485. A reserve was made for 10 vehicles of an experimental batch. But the trouble came from where they did not expect.

Arms Minister D. Ustinov was looking for an industrial base for the production of missiles, including designs by S. Korolev. And now he is a twist of fate - he "liked" the Dnepropetrovsk Automobile Plant. By the decree of the Council of Ministers of May 9, 1951, DAZ was transferred to the "defense industry" and it received the number 586 (now it is "Yuzhmashzavod") and the new designer M. Yangel.

Sharp turns of fate

After the adoption of the R-1 rocket and in the conditions of approaching the completion of work on bringing the R-2 rocket into service, the problem arose of their serial production in mass quantities to build up the country's military potential. At OKB-1 in Podlipki, there was an experimental plant for about ten thousand workers, but its capacity was insufficient for mass production of missiles, and the possibilities for expanding the plant were limited by the territory. At first, the series was supposed to have a plant number 66 in Zlatoust, built since 1949, but due to the international situation, which was aggravated (the so-called "Berlin Crisis of 1949"), the government decided to accelerate the search for a new plant.

In order to select an appropriate plant for the serial production of missiles, a government commission was created at the end of 1950, headed by the Minister of Armaments D. F. Ustinov. According to Ustinov's plan, it was necessary to select a sufficiently powerful and promising plant from any department, preferably a relatively "young" one - to facilitate "expropriation" and re-profiling. The commission first visited the plant in Zlatoust, then went to Kiev (it is said that Khrushchev protested against Kiev: "You cannot declare the capital of Ukraine a closed city"), but later settled on a young automobile plant in Dnepropetrovsk.

Even in the pre-war years, the city became the center of full-cycle metallurgical production. Around there were factories supplying the necessary raw materials, there was a powerful energy base. The industrial center had a large number of skilled workers, there were many universities and technical schools where it was possible to organize the training of relevant engineering and technical workers.

JV Stalin approved the choice of the government commission. The discussion did not last long. The Minister of the Automotive and Tractor Industry tried to shyly argue that the country needed trucks. To this, JV Stalin said that if we have missiles, then there will certainly be trucks, and if there are no missiles, then, perhaps, there will be no trucks either.

The fate of the Dnipropetrovsk plant was decided.

Rockets instead of cars: the first Soviet ballistic missile R - 1

On May 9, 1951, the Resolution of the Council of Ministers of the USSR No. 1528-768 "On the transfer to the Ministry of Armament of the Dnepropetrovsk Automobile Plant of the Ministry of Automotive and Tractor Industry and the Dnepropetrovsk Tire Plant of the Ministry of Chemical Industry and their unification into a single Dnepropetrovsk Machine-Building Plant No. 586 of the Ministry of Armament" was issued.

The next day, order No. 312 of the Minister of Armaments of May 10, 1951 was issued:

Pursuant to the Resolution of the Council of Ministers of the USSR dated May 9, 1951 No. 1528-768 “On the transfer of the Dnepropetrovsk Automobile Plant to the Ministry of Armament …

I order:

1. To include the Dnepropetrovsk Machine-Building Plant in the enterprises of the 7th Main Directorate.

2. To appoint a commission to accept the plant …"

The Dnepropetrovsk Automobile Plant becomes a secret rocket enterprise "mailbox No. 186", the full closed name is State Union Plant No. 586. workshops create a special military unit. Since May 1951 for many years, any mention of the Dnepropetrovsk Automobile Plant completely disappears from the press.

Department of the chief designer of DAZ (V. Grachev in the first row in the center)

The team of designers-motorists was forced to disintegrate: someone went to Minsk, to a car plant; some returned to GAZ; most of them remained at the new plant and were retrained as "rocket scientists". V. Grachev in June 1951 was asked to move to the Moscow ZIS by the deputy chief designer and deal with new technology. The serial production of amphibians "485" according to the DAZ documentation was also transferred to the ZIS: they were necessary for the engineering troops of the Soviet Army. Together with Grachev, two research DAZ-485 and GMC-353 were transported to Moscow. At the new location, everything had to start virtually all over again. But at ZIS they understood that such work was inevitable, and for its failure one could get a “big hat”. Therefore, the plant threw a lot of effort into the development of the now ZIS-485. Engineer S. Deev became the leading designer of the car.

In August 1951, a special testing bureau "485" was formed and a separate "closed" workshop for assembling new machines was created. The results of such work soon made themselves felt: at the end of July 1952, the first four serial ZIS-485 were produced, and in August - already 17 machines. By the end of 1952, according to the plan, 100 vehicles were assembled. Subsequently, the production of ZIS-485 reached 285 - 286 units per year. The car was mass-produced from 1952 to 1963. In total, about 1200 amphibians were manufactured.

At the beginning of 1953, the amphibian ZIS-485 (from June 1956, ZIL-485) under the designation BAV ("Big waterfowl car") began to enter the troops, where they were met very well. They have found application as self-propelled landing craft, self-propelled ferries, transport vehicles capable of operating in various environments. Later, these machines (about 300 units in total) were used in the national economy. In some cases, they are still in operation, for example, as an amphibious trawler for fishing or transporting fishing teams by land and water.

ZIL-485 of the Moscow plant

BAS on trials

On the exercises

Amphibious trawler UROM-2 based on ZIL - 485A

Floating attraction BAV in England

The appearance in 1950 of the "485" car caused a strong technical resonance in the Soviet automobile industry. The ideas embodied in it had a great, revolutionary impact on increasing the cross-country ability of wheeled vehicles and on the development of automotive technology in general. Since then, almost all domestic all-wheel drive vehicles with high cross-country ability (both general purpose and special ones with a carrying capacity of 2 tons and above) have a similar transmission scheme. Mastering the mass production of such machines was the undisputed priority of the USSR, which was appreciated by experts from all over the world.

Table 2. Technical data of the amphibious BAS

Carrying capacity, kg:

on land - 2500;

on the water - 3500.

Total weight (with crew and cargo), kg - 9850.

Dimensions (LxWxH), mm - 9533 x 22475 x 2635.

Clearance, mm - 289.

Turning radius on the ground, m - 10, 44.

Maximum travel speed, km / h:

on paved roads - up to 75;

on the water - 10, 8.

Loading platform area, m2 - 10, 44.

Cruising range, km:

on the highway - up to 640;

on water - up to 80 (8 hours of non-stop running).

BAS, winter 1956

Loading 85-mm cannon D-44 on BAV, Central Asia May 1957

In conclusion, a few words about the chief designer V. Grachev.

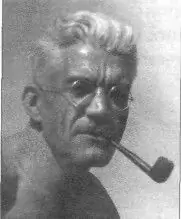

Grachev Vitaly Andreevich (January 23, 1903 - December 24, 1978)

Born January 23, 1903 in Tomsk, in the family of a ship owner. Father, a native of peasants, founded his own business, his mother worked as a zemstvo doctor. Vitaly Andreevich was the fifth child in a large family. He left the family early for an independent life.

From an early age he was interested in engineering, served as a technician in aviation units, then worked as a projectionist.

In 1923 he entered the Tomsk Technological Institute, from which in 1927 he was expelled for "non-proletarian origin".

In December 1931, as unemployed, he was mobilized to the technical department of the Nizhny Novgorod Automobile Plant, which was just under construction.

In 1936, driving an independently developed car - a light all-terrain vehicle "GAZ-AAAA" - participated in the famous Karakum-Pamir motor rally on the route Gorky - Pamir - Moscow.

V. A. Grachev managed to withstand the years of repression, and after the support of the People's Commissar Sergo Ordzhonikidze, he began independent design work.

In 1937, under his leadership, a three-axle cargo-passenger vehicle GAZ-21 was developed on the basis of which a seven-seater passenger car and two armored vehicles were subsequently created.

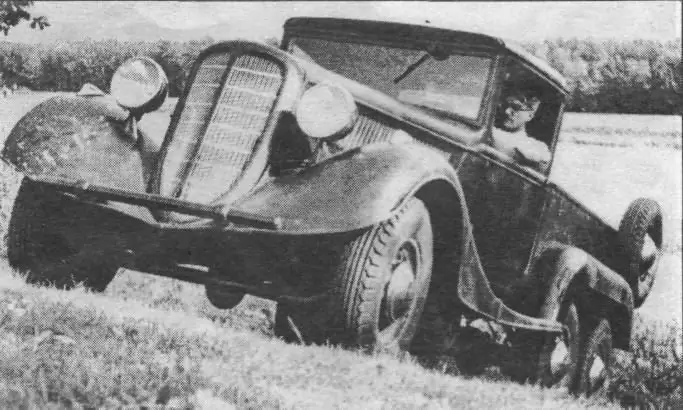

V. Grachev driving a GAZ-21

In 1938-1939. designs the first Soviet light all-terrain vehicle GAZ-61 (the first Soviet four-wheel drive vehicle), which to this day has remained unsurpassed in dynamics and cross-country ability for cars of this class. This car went into production at the end of the 1940s.

Light all-terrain vehicle GAZ-61

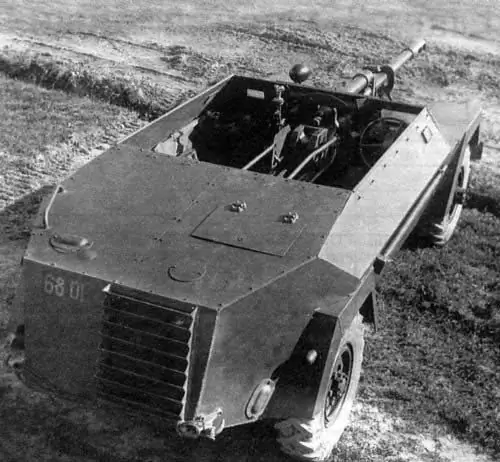

In 1941-1944. under his leadership, the army jeep GAZ-64 and armored vehicles BA-64 and BA-64B based on it, the GAZ-67 car, as well as the world's only wheeled self-propelled gun GAZ-68 (KSP-76) and other samples of wheeled military equipment were developed …

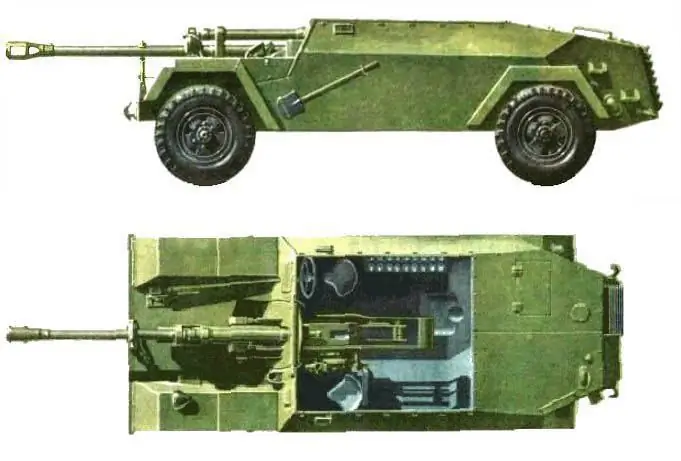

Self-propelled gun KSP-76. view of svkrhu

KSP-76. side and top drawing

In September 1944 V. A. Grachev was appointed chief designer of a car plant in Dnepropetrovsk, where he created an army amphibious vehicle GAZ-485 (BAV).

Since 1951, he is the deputy chief designer, and since 1954. - Chief Designer of the Special Design Bureau of the Automobile Plant named after I. V. Stalin (later the plant named after I. A. Likhachev) in Moscow, appointed on the initiative of the Minister of War of the USSR, Marshal of the Soviet Union G. K. Zhukov). Here, under his leadership, the ZIL-157, ZIL-134 vehicles, the ZIL-135K missile carrier (the world's only serial chassis with two automatic transmissions), the BTR-152A, BTR-152B armored personnel carriers, medium wheeled artillery tractors, multipurpose army transporters and installations based on them.

ZIL-134

Vitaly Andreevich Grachev - the creator of the ZIL-135l car, on which it was possible to transport cargo exceeding the weight of the car (for the first time in the world he used plastic for the manufacture of the body). He created the ZIL-167 snowmobile. To increase the cross-country ability of the machines, the designer installed a jet engine on them, to increase maneuverability, he used aircraft landing gear.

ZIL-135L

ZIL-167

After the unsuccessful landing of the Vostok-2 spacecraft, which almost ended in tragedy (March 19, 1965, cosmonauts Pavel Belyaev and Alexei Leonov), at the suggestion of Sergei Pavlovich Korolev, Vitaly Andreevich began the development of a search and rescue mobile complex with an absolute passability of the ZIL-complex machine. 49061 ("Blue Birds"), equipped with direction finding technology, which made it possible to arrive at the cosmonauts landing site in a short time, even in terrain that was considered impassable.

"Blue Birds" V. Grachev

Under the leadership of V. A. Grachev, 88 new car designs were created, which ensured for the USSR a leading position in the world in the field of cars for difficult-to-pass conditions.

Awards:

- By the Decree of the Council of People's Commissars of the USSR No. 485 dated 1942-10-04 Vitaly Andreevich Grachev was awarded the Stalin Prize of the III degree "For the development of new designs of the GAZ-64 car and the BA-64 armored car."

- By the Decree of the Council of People's Commissars of the USSR No. 981 of 1951-14-03 he, as part of the team, was awarded the Stalin Prize of the III degree "For the creation of a new model of the car (three-axle amphibian GAZ-485)."

- Awarded with the Orders of Lenin, the Order of the Red Banner of Labor and medals.