- Author Matthew Elmers elmers@military-review.com.

- Public 2023-12-16 21:49.

- Last modified 2025-06-01 06:23.

The driver display of the LATIS video system shows one of the options for how Situational Awareness of the Ground Vehicle can be implemented. The image shows a combined front glass surface with three “docked” views: the center thermal image (projection of the vehicle's apparent path), rear view (copying the image from a conventional rearview mirror), and “wing mirrors” at each bottom corner of the main display. It also displays speed (top left), geographic coordinates (top right), and compass heading (bottom center). This composite image (and its elements) can also be shown to the commander and any infantry in the rear of the vehicle.

The increased use of military vehicles with closed doors and hatches in urban environments has led to an increase in capabilities called Situational Ground Vehicle Awareness (SIOM). In the past, SIOM was no more complicated than a windshield, side windows, and a pair of rear-view mirrors. The introduction of armored combat vehicles (AFVs) into the urban environment and the threat posed by improvised explosive devices (IEDs) and rocket-propelled grenades (RPGs) have led to the need to create new peripheral vision capabilities

SIOM systems emerged from an evolutionary process that has accelerated since about 2003 due to the realities of the war in Iraq and other war zones. And the process itself began with the addition of night vision to the vision and observation systems of drivers of armored combat vehicles (AFVs), which could theoretically participate in tank battles on the fronts of Central Europe. Night vision systems with image intensifier - II or I2 have opened the way for thermal and infrared observation devices.

In a closed car, the driver usually uses a periscope, while the shooter has a fire control system (FCS), including visual aids, and the commander has some kind of panoramic view. Although technology has improved the range and resolution of these systems, their coverage (field of view) remains the same. With the deployment of troops against the regular army in 1991 in the Iraqi desert, the European NATO concept of operations remained unchanged due to the fact that the number of close combat in urban space was relatively small.

However, after the initial euphoria from the 2003 invasion of Iraq passed and the modern threat of asymmetric war arose, the crews of main battle tanks (MBT) and other armored combat vehicles (wheeled and tracked) were forced to fight in urban space. Driving through narrow streets, the driver was unable to see what was happening from the side or behind the car. It was enough for just one person to sneak along the street and put something like a mine or other IED under the car, and as a result, it turned out to be immobilized or damaged.

Likewise, versatile cars and trucks faced the same threats and were gradually additionally armored, while the protection certainly improved, but as a result, the visibility around the car deteriorated. Thus, they actually found themselves in the same tactical situation as the AFV. What these machines lacked was some form of circular or local (intra-zone) LSA (local situational awareness) situational awareness.

Like many developments, LSA systems did not appear overnight, but rather slowly evolved as the technology became available. The process began with the need to improve the driver's all-round visibility, which resulted in the appearance of thermal imaging devices, as well as observation devices with increased image brightness. By the end of the 90s, when a new generation of thermal imaging devices was introduced, the driver no longer needed to look into a periscope "observation" device, but rather looked at a display similar to a television screen.

Driver's Vision Enhancer from Raytheon DVE AN / VAS-5 with cooled long-wave infrared (LWIR - near [long-wave] infrared; 8-12 microns) receiver based on strontium barium titanate, which has a video transducer matrix size 320x240 pixels, has a frontal field of view of 30x40 degrees and is a typical representative of such devices. (The US Army awarded a contract for the bulk of the DVE products to DRS Technologies in 2004, while BAE Systems did receive its share of their production in 2009).

In the UK, the introduction of thermal imaging began in 2002, when the DNVS 2 (Driver's Night Vision System - dual channel) from BAE Systems (now Selex Galileo) was adopted for Titan AVLB (Armored Vehicle -Launched Bridge - armored bridgelayer), Trojan ETS (Engineer Tank System - engineering tank) and Terrier CEV (Combat Engineer Vehicle - defensive combat vehicle). It has also been fitted to BvS10 Viking articulated all-terrain vehicles with additional British Marine Corps armor and to some vehicles in the Netherlands.

Colin Horner, VP of Marketing and Sales for Selex Galileo Land Systems, describes the DNVS 2 as a forward facing armored unit mounted in the front of the hull, which includes a color CCD (Charge Coupled Device) camera with field of view of 64x48 degrees and thermal imager LWIR 320x240 (with a field of view of 52x38 degrees). The driver sees the image on an 8, 4-inch color LCD display mounted on the dashboard. Subsequently, Ultra Electronics supplied daytime cameras to cover the flanks of the tank.

The Caracal DVNS 3 was later developed. It has a wider field of view of 90x75 degrees for a CCD camera, as well as options for a color or monochrome version. The Caracal was installed on the British Army's additionally armored Challenger 2 MBTs, Challenger ARVs, M270B1 and M270B2 MLRSs.

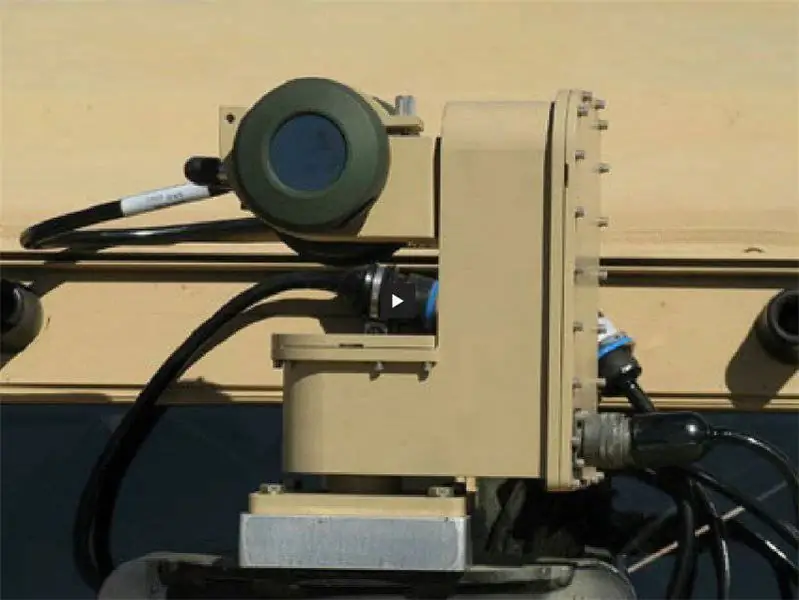

Illustrative illustration of the Tactical Wheeled Vehicle Module (DVE-TWV) included in the current generation of DVE-FOS systems. The module is a model AN / VAS-5C from DRS Technologies and is also installed on HMMVW

TUSK is developing

Since the American army is forced to deploy the Abrams MBT in the urban environment, it has developed a TUSK (Tank Urban Survivability Kit - a set of additional equipment and armor for a tank that increases its combat capabilities in urban conditions), an integral part of which is the driver's rear view camera DRVC (driver's rear-view camera). The DRVC is based on the Check-6 device from BAE Systems, it houses an uncooled vanadium oxide microbolometer with a 320x240 (or 640x480) LWIR matrix (originally developed for the AN / PAS-13C thermal imager of the same company). The DRVC integrated into the Abrams rear marker was originally ordered in 2008 and has since been installed on Bradley, MRAP (mine-resistant, ambush-protected) vehicles and the Stryker family of vehicles …

The exact composition of the TUSK kit for the Abrams tank, determined by its developer (above). An inquisitive reader will of course find the differences by comparing the top and bottom photos showing the TUSK kit.

In September 2009, the Army Electronic Communications Command awarded each of BAE Systems and DRS Technologies a $ 1.9 billion contract (the so-called contract with an indefinite period and quantity of delivery) for the production of an infrared sensor system that could provide a round-the-clock All-weather visibility for US Army and Marine ground vehicles. The complex, known as the DVE-FOS (Driver's Vision Enhancer Family of Systems) family of driver vision enhancers, is a development of the AN / VAS-5 DVE (although not an LSA all-round view system) and consists of four options.

DVE Lite is designed for long-haul trucks and tactical vehicles, while DVE TWV uses a panoramic module for tactical wheeled vehicles (TWV). DVE FADS (Forward Activity Detection System) provides long-range detection, surveillance and tracking of suspicious activity (for example, related to the installation of IEDs) and, finally, DVE CV (Combat Vehicles) is suitable for installation on combat vehicles. cars.

The availability of rear-view systems led to the introduction of repeater displays inside the armored personnel carriers, on which the soldiers in the rear of the vehicle could see the situation outside before landing. It has also in some way led to a decrease in the number of claustrophobic attacks in the "armored box" and a decrease in the number of seasickness among the landing.

After gaining the opportunity to have front and rear visibility on the vehicle, a very short step remained - installation of cameras and sensors on the body in order to cover the sides of the vehicle and create a circular LSA. After that, it began to be considered as an inalienable requirement. Such systems have improved self-defense against nearby threats, allowing you to transfer targets to the combat module or use personal weapons, firing through the embrasures of the vehicle. At the same time, these LSA capabilities have minimized the need for troops to dismount without delay in order to ensure safety around the vehicle.

In Great Britain, the first SIOM system with all-round visibility for the British army was supplied by Selex Galileo for the Mastiff 2 6x6 armored patrol vehicles, which entered service in June 2009. This six-camera system has a forward-facing thermal imaging camera, a reversing camera and two cameras on each side of the vehicle. “The requirement for visibility around the car was more about maneuvering, not about identifying a threat,” Horner said. Similar systems were supplied for the Buffalo, Ridgback, Warthog and Wolfhound AFVs.

With ground movement, either in urban or rural areas, has become the target of an increasing number of IEDs deployed under or near known convoy routes, it is virtually impossible to apply countermeasures directly to each such threat. As a result, a comprehensive deep hike was applied to solve this problem and a variety of detection tools were tested.

Before the advent of solutions for near-circular viewing, an early response to the need for SIOM and anti-IED devices was the rapid proliferation of mast sets of sensors and sensors equipped with night and day cameras on many military vehicles. In those places where the IEDs were installed, the soil around them is disturbed and when observing through a thermal imager, the difference between the images of the "fresh track" and the surrounding earth or concrete is visible. These sensor units (heads) were mainly intended for aircraft, but they were "turned over" and installed on the retractable mast of the machine, and by means of a calculating unit they were combined with a display / control panel installed inside the machine. Currently, the crews have devices for determining disturbed soil, which can serve as an indicator of the presence of an IED installed ahead of the route.

In addition, these kits gave the crew a very small amount of LSA at maximum descent. Full short-range coverage of the area directly at the sides of the vehicle is impossible due to the shielding effect of the vehicle itself.

Various MRAP vehicles are equipped with a mast-mounted optical sensor system developed by Lockheed Martin Gyrocam Systems

Mast-mounted sensor

Typical of this is VOSS (Vehicle Optics Sensor System), originally developed for the US Marine Corps by Gyrocam Systems (acquired by Lockheed Martin Missiles and Fire Control in mid-2009) for the 360 program. infantry has requested a mast-mounted surveillance system for their MRAP-class vehicles that will help detect roadside IEDs. In 2006, Gyrocam delivered 117 ISR 100 sensor units, each equipped with a medium wave infrared (MWIR; 3-5 micron) thermal imager with a 320x256 matrix; three-chip high-resolution CCD TV camera; a single-circuit CCD TV camera for low illumination and an eye-safe laser illuminator; all devices of the optoelectronic system are housed in a 15 (381 mm) diameter slewing ring.

This program was quickly adopted by the US Army and became part of the VOSS demining and explosive ordnance disposal program. In May 2008, the US Army awarded Gyrocam a $ 302 million VOSS Phase II contract with a potential volume of 500. The VOSS II optoelectronic station is based on the Gyrocam ISR 200 or ISR 300 using a high resolution MWIR 640x512 thermal imager.

VOSS systems are installed on Buffalo, Cougar JERRV (Joint EOD Rapid Response Vehicle), RG31 and RG33, all MRAP class vehicles, mainly used in Iraq and Afghanistan. Due to the fact that the company became Lockheed Martin Gyrocam Systems, ISR 100, 200 and 300 products merged into one product line under the designation 15 TS.

Since 2007, FL1R Systems Inc, Government Systems (FSI-GS) has been offering a mast optoelectronic station for ground vehicles based on the Star SAFIRE III (Sea-Air Forward-looking Infrared Equipment) air use) 15 '' diameter. The sensor equipment known as Star SAFIRE LV (Land Vehicle) includes the MWIR 640x512 thermal imager; color CCD TV camera with magnification; color CCD camera of the "spyglass" type (long-range, narrow field of view); TV camera for low light; eye-safe laser rangefinder; laser illuminator and laser pointer. FSI-GS also offers a similar version of its 9”Talon with a similar set of sensor equipment.

There is a wide range of sensors for inclusion in modern SIOM systems; virtually all are off-the-shelf and many are offered by civilian security equipment suppliers. The list of companies and products is extensive, a kind of pick and mix problem, depending on the exact requirements for the machine, the time frame in which additional equipment needs to be made and the funding available.

Most cameras are traditional CCD models available in monochrome, color and low illumination (VIS to FIR), whose lenses generally meet wide field of view requirements. Many supply high definition imaging devices similar to commercial high definition televisions, which is becoming increasingly important for unambiguous target recognition.

A family of ruggedized camera modules specifically designed for LSA applications and typical of such applications are supplied by California-based Sekai Electronics. The modules are supplied as either color or monochrome CCD cameras, in a sealed, EMI-protected aluminum housing with a scratch-resistant sapphire window, with fixed iris lenses of various focal lengths. The horizontal resolution of the cameras is> 420 lines, and the video output is NTSC or PAL (for color) and EIA or CCIR (for monochrome).

Likewise, thermal imagers are available on the market in a variety of formats and configurations depending on the role and application. Thus, cooled and uncooled thermal imagers with LWIR, MWIR or short-wave (SWIR; 1, 4-3 micron) detectors and matrices from 320x240 to 1024x768 and more are available for consumers. While some original equipment manufacturers (e.g. FSI-GS) produce their own thermal detectors integrated into their own products, others purchase receivers (detectors) from specialized manufacturers such as France's Sofradir (specializing in cooled detectors with mercury-cadmium telluride technology) and its subsidiary ULIS (which manufactures only uncooled systems).

For ULIS, the specific SIOM market is relatively new. The company's CTO Jean-Luc Tissot said that “ULIS has only been delivering products for LSA applications for a few years,” although the company's products have been part of other vehicle systems before. Uncooled thermal imagers are inherently less expensive and easier to maintain than current cooled receivers (detectors), and advances in image resolution have made them increasingly attractive. The company is marketing three LWIR detectors (8 to 14 micron range) in amorphous silicon with 384x288, 640x480 and 1024x768 matrices and 17 micron pixel pitch to several customers including Thales Canada.

Cameras and thermal imagers can be installed independently or in pairs, depending on the purpose. Copenhagen Sensor Technology, a Danish company, is using Eurosatory to showcase its involvement in improving driver vision and LSA systems for vehicles, as well as sensor kits for warheads and long-range surveillance.

British Army Panther communications and command vehicle, equipped with a full TES kit. The Forward Vision Sensor is a thermal imager, and Thales 'TES kit also includes Thales' VEM2 module as a rearview camera

General vehicle architecture (GVA - Generic Vehicle Architecture)

In the early stages of SIOM development, most of the development work was carried out by specialized companies in response to urgent operational requirements of users. Today, a more structured approach is being considered due to the fact that there is an improvement of the original systems developed for these urgent requirements. In the United Kingdom, for example, such systems were given higher priority by the Department of Defense, leading to the release on 20 April 2010 of Defense Standard 23-09 (DEF-STD-00-82), which describes a generic vehicle architecture (GVA).

Another UK defense standard for SIOM systems (Intermediate Option 1 issued August 2009) is 00-82, Vehicle Electronics Infrastructure Related to Video Transmission via Ethernet VI-VOE (Vetronics Infrastructure for Video Over Ethernet). It establishes various mechanisms and protocols to facilitate the distribution of digital video over Ethernet networks, primarily over Gigabit Ethernet.

At Defense Vehicles Dynamics (DVD) at the Millbrook Proving Grounds in the UK, BAE Systems Platform Solutions (which brought together the imaging, integration and management expertise of its UK plant in Rochester with the advances in sensor technology from the Texas plant) showed the capabilities of LATIS (Local And Tactical Information System), integrated into the Panther machine in accordance with the emerging GVA requirements.

With systems quickly becoming “sensor invariant,” LATIS is more of an architecture than just cameras. Rob Merryweather, Program Manager for British War Machines at BAE Systems Platform Solutions, describes LATIS as offering: a driver display; use of smart symbols; built-in learning; motion detection and target tracking; digital mapping; combining images; and the ability to automatically target and destroy targets by external target designation commands.

The company participates in the GVA process and, according to Director of Business Development David Hewlett, initial efficiency, the foundation of systems such as LATIS is "a scalable and flexible architecture with high bandwidth and low latency (latency)."

Waiting time is defined as the time elapsed from the moment a photon hits the sensor head until the final image is displayed on the screen, measured in milliseconds. It takes less than 80 milliseconds of latency to get a system suitable for driving.

Other elements of the LATIS project are displays (fixed and helmet-mounted, possibly using a Q-Sight display from the same company), processor and power requirements, plus control of such systems.

The Thales Group is also a regular exhibitor at DVD as the UK division recently developed a new electronic architecture for a versatile machine. This architecture was created to comply with the new GVA standard of the British Department of Defense. Thales UK has been involved in identifying the optimal GVA since early 2009 and showcased a “challenger architecture” at the show, suitable for future versatile machines.

The Thales architecture features new software to improve the integration of multiple systems on board the vehicle. The functionality shown on the DVD included a common human-machine interface for the GVA, providing built-in access to vision systems, sniper detection, energy management, and operational status monitoring.

Live video distribution is based on another new defense standard (00-82 VIVOE). It includes a new line of LSA digital cameras that connect directly to the vehicle's Ethernet data bus. Thales describes VIVOE as a "flexible, modular or scalable configuration," adding that being digital, it "facilitates the use of auto-sensing, target tracking and many other image processing algorithms." The overall result is improved efficiency and therefore increased survivability.

The Canadian and UK subsidiaries of the Thales Group, as key players in the vehicle architecture process, work together to leverage their LSA expertise to meet the specific requirements of the individual purchaser. Thales' work includes thermal imaging cameras for drivers, including the TDS2 (Thermal Driver's Sight 2) thermal imager, Driver's Vision Enhancer 2 (DVE2), Vision Enhancement Module 2 (VEM2), and the driver's remote vision enhancer Remotely Operated Driver's Vision Enhancer 2 (RODVE2), available in analog and digital form.

“Since 2004, about 400 TDS instruments have been purchased for the British Army Panther command vehicle,” a Thales UK spokesman said. Prior to shipment to Afghanistan, 67 vehicles were upgraded to the Theater Entry Standard (TES), including the addition of a rear view VEM2 device (among other improvements), delivered as part of urgent requirements in March - August 2009.

The addition of a thermal rearview camera is now standard for driver vision and surveillance systems. “When we add onboard cameras or provide all-round visibility, the LSA system appears,” a Thales Canada spokesman said. Working together, Thales UK and Thales Canada delivered their first Integrated Local Situational Awareness (ILSA) for an unnamed customer in 2008, followed by another for another customer. This analog system consists of two RODVE cameras, six color cameras for low lighting, four 10.4-inch programmable LCDs and a signal distribution unit (SDU).

Based on ILSA, Thales UK is currently promoting a digital version that is DEF-STD-00-82 compliant and will also be DEF-STD-23-09 compliant. This open architecture uses the VEM2 module for front and rear vision devices, plus television cameras, but is essentially invariant to sensing components (sensors). With a field of view from 16 to 90 degrees, the VEM2 uses uncooled LWIR 640x480 receivers from the French company ULIS. Thales describes the system as a "flexible, modular and scalable configuration," adding that the digital system "allows for auto-sensing and target tracking algorithms."

Thales Canada currently offers a Local Situational Awareness System (LSAS) consisting of RODVE2 (also with LWIR 640x480 receivers) and VEM2, camera, SDU and HMI. In addition, the company has supplied various thermal imaging driver surveillance systems (RODVE2 and VEM2) for seven types of Canadian vehicles, including the Leopard 2 MBT, M11Z armored personnel carriers, LAV and Bison vehicles, which have been in operation in Afghanistan since 2008.

Selex Galileo's Colin Horrner, meanwhile, said that much of the company's SIOM work was self-financed. At the 2010 Farnborough Airshow, the company showed the general LSA system. “Everything about it is designed to tailor solutions to meet the needs,” Horner said. In order to facilitate integration with existing machines, the system has its own functionality due to the display unit of information processing. Several display units can be installed in series inside the machine.

The emergence of developments in the field of LSA

In the US, the Sarnoff Corporation is developing systems designed for what it describes as "open vehicle space" and "closed vehicle space". For the first category, Sarnoff created the HMMWV image fusion system for vehicle drivers; it used conventional video and LWIR devices. The system offers extended dynamic range and depth of field for day and night driving. In addition, it has close-range surveillance, identification, detection and tracking capabilities. There is also "circular situational awareness and understanding" for an automatic threat detection system known as CVAC2 (Computer Vision Assisted Combat Capability), which is being developed by the US Marine Corps Combat Laboratory.

The CVAC2 sensor head consists of a fixed circular installation containing 12 night cameras and 12 day cameras (installed in pairs one above the other). In addition, there is a pair of GPS receivers and panoramic platforms (with a circular field of view), an LWIR thermal imager, a day / night zoom camera, and a laser rangefinder. The system combines input signals from a number of different sensors through its Acadia I ASIC video accelerator to produce a composite image.

The UK and the US are not alone in developing SIOM systems. In addition to these countries, such systems are being developed by the Belgian Barco, the German Rheinmetall and the Swedish Saab.

Display manufacturer Barco offers "rearview container" and "panoramic container" as an LSA solution. In the company's literature, the latter is described as an open digital architecture system capable of combining up to eight cameras and is compliant with the DEF-STD-00-82 standard. Image processing and stitching techniques allow 180-degree and 360-degree panoramic views to be presented on a single screen. It also has built-in image fusion and target recognition capabilities. The company has confirmed the presence of one unnamed buyer.

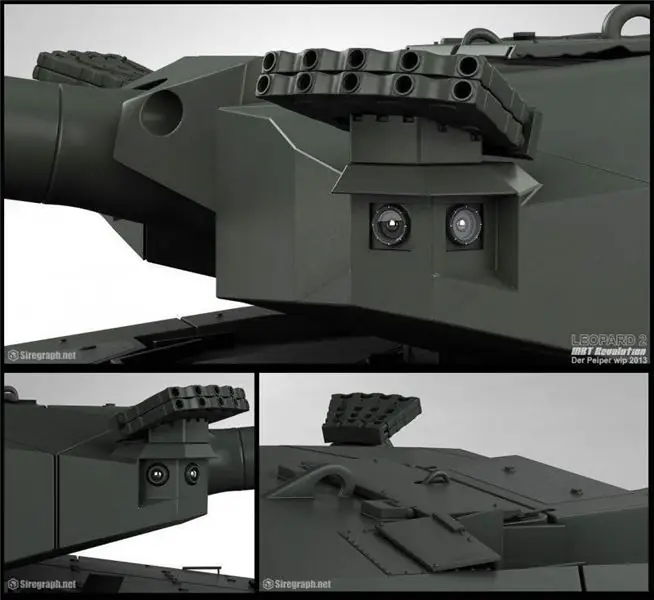

Rheinmetall Defense Electronics introduces a situational awareness system (SAS) for tanks with a circular coverage area in azimuth (± 30 degrees in elevation). This is achieved through 4 three-sensor blocks in each corner of the tower; the system was shown on the Leopard 2 MBT. The basic sensing component is a high resolution daytime color camera with uncooled thermal imaging receivers as an option. The displays have a picture-in-picture characteristic, as an option, it is possible to introduce the function of switching to the tracking mode of the target in case of its detection by any element of the system.

The LSAS, developed by Saab's Defense and Security Solutions Division, is based on six uncooled LWIRs (7.5-13.5 microns) 640x480 vanadium oxide microbolometers, designated FSI-GS Thermo Vision SA90, providing 270-degree flank coverage and AFV stern (the front quadrant is monitored by any driver's thermal imager) and the proprietary Video Distribution System of the same company.

At one of the Farnborough airshows, Israel's Elisra Electronic Systems unveiled the IR-Centric, which, although designed to be installed on airborne platforms, has a similar application in ground systems. It uses an image processing system from existing IR sensors of missile warning systems (for example, the PAWS system of the same company) in order to obtain a panoramic image that can be displayed on the pilot's helmet display. While MWIR detectors (receivers) require a minimum resolution of 256x256, optics with a wide field of view and a high frame rate in conjunction with a wideband channel, the secret lies in the SAPIR (Situational Awareness Panoramic infraRed) and display algorithms. technologies. Some AFVs already have infrared signaling devices for attacking missiles; such an application for ground vehicles is obvious, although such systems have not yet shown their capabilities.

Previously seen as “optional features,” driver surveillance systems have moved from AFVs to support vehicles and, with the advent of new threats and technologies, have evolved into full-fledged LSA systems. Opportunities previously seen as “nice to have” are now considered an integral part of a land vehicle.

Situational awareness cameras included in the Rheinmetall modular upgrade kit are installed on the Leopard 2 MBT