- Author Matthew Elmers elmers@military-review.com.

- Public 2023-12-16 21:49.

- Last modified 2025-01-24 09:17.

In the early nineties, the Neue Gepanzerte Plattform or NGP (New Armored Platform) project was launched in Germany. His goal was to create a whole family of promising armored combat vehicles of different classes for the future rearmament of ground forces. For a number of reasons, NGP development was halted long before the desired results were obtained. But some of the developments of this program later found application in new projects.

Bold plans

The goal of the NGP program was to create new AFVs capable of replacing all available samples of the Bundeswehr. According to the established work schedule, until 1996 the army had to determine the tactical and technical requirements for the family, and until 2005 it was planned to carry out development work. In 2005-2009. were going to put into service an armored personnel carrier based on NGP, in 2015 the main tank was expected, and from 2020 - all other samples.

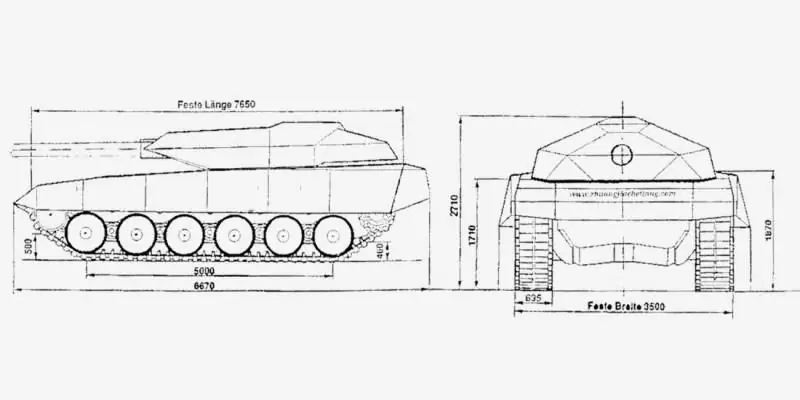

The project provided for the creation of three unified platforms for different purposes. Plattform A was considered as MBT, Plattform B was the basis for armored personnel carriers or infantry fighting vehicles, and it was proposed to build various self-propelled units and auxiliary equipment on Plattform C. The three platforms were supposed to be based on common solutions.

However, most of these plans were not fulfilled. In 1998, the NGP project was reduced to Neuer Schützenpanzer or NeSPz ("New BTR"), and in 2001 it was finally closed. By this time, it was only possible to develop and test the EGS technology demonstrator machine. In the future, new projects were launched that significantly differed from the large and comprehensive NGP program.

Protection issues

The exact security requirements for NGP platforms have not yet been published. At the same time, technical proposals from developers and some solutions to increase the level of protection are known. Some of them "survived" the NGP program and find application in new developments.

Wegmann, in its preliminary design of the NGP platform, was able to provide frontal projection protection equivalent to 1000-1300 mm of homogeneous armor. Such characteristics were achieved through the use of combined and spaced armor with rational angles of inclination. It was assumed that MBT and infantry fighting vehicles of new types will have the same anti-cannon protection.

Since 1995, several NGP participants have studied the issues of creating active protection complexes and optoelectronic suppression. Soon, the concept of the COEP ASSS (Abstandswirksames Softkill-Schutzsystem) appeared, on the basis of which the MUSS (Multifunktionales Selbstschutz-System) product was then created. For obvious reasons, this complex never made it to NGP armored vehicles, but it was still used. Tests of such a COEP were carried out on the German MBT Leopard 2 and the British Challenger 2. In 2006, MUSS was adopted as part of the equipment of the Puma BMP for the Bundeswehr.

The development of KAZ for NGP was also carried out. In the late nineties, the AWiSS complex was brought to testing. They did not manage to bring it to the closure of the program, but the main developments then found application in new projects. However, KAZ is still not used on Germany's own tanks.

Reinforced armament

The project of the main tank Plattform A or NGP-KPz provided for an increase in firepower due to a fundamentally new weapon. Several companies from Germany and other countries developed the 140mm Neue Panzerkanone 140 (NPzK-140) smoothbore gun. By increasing the caliber and introducing a new shot, the muzzle energy could be increased to 20 MJ with an increase in combat characteristics.

The 140 mm gun did not advance beyond the ROC. Due to the closure of the NGP program, such a gun was left without a possible carrier, and the work actually stopped. After many years, the experience of the NPzK-140 project was used to create an experimental 130-mm cannon from Rheinmetall. This product was first shown in 2016, but its prospects are still in question. The possibility of using such weapons in the German-French project MGCS is being considered.

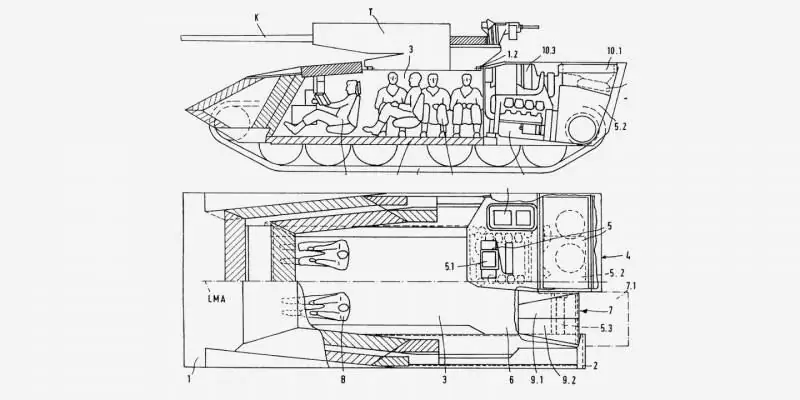

Calculations showed that a high-performance shot for a 140 mm cannon would be too large and heavy. An automatic loader was developed to work with it. Several NGP participants offered their own versions of the AZ, which could hold up to 30 shells. The developments on the topic of AZ were not implemented and implemented. In the future, such solutions may find application in the MGCS project.

In the Plattform B project (NGP-SPz), the possibility of using an uninhabited tower with machine-gun and grenade launcher armament, controlled remotely, was studied. From the point of view of further implementation of developments, such solutions turned out to be almost the most successful in the entire NGP program. To date, German enterprises have developed and are offering on the market a number of remotely controlled weapon stations.

The problem of mobility

All samples of the NGP family were planned to be built on a tracked chassis. Three platforms for different purposes were supposed to have the maximum degree of unification that could simplify development, production and operation. At the same time, at the stage of competitive development, various options for architecture and equipment were used.

Wegmann offered a versatile chassis with the ability to build a tank or armored personnel carrier. The engine was placed in the stern with a shift to the right - to the left of it there was space for the AZ or the landing passage. The project from Maschinenbau Kiel, in turn, provided for a front-engine layout with the release of the center and stern for combat equipment or an airborne compartment.

Both approaches have subsequently been repeatedly used in new projects. In this case, the choice of the AFV architecture was carried out in accordance with the class of technology. Probably, this state of affairs will continue in the future, when creating new samples. For example, in the context of the MGCS project, both front and rear engine placement are now considered.

High automation

In accordance with the requirements for NGP, the crew of promising armored combat vehicles was supposed to consist of only 2 people. The NGP-SPz vehicle was also supposed to carry 6-8 paratroopers. Fulfillment of such requirements, primarily in terms of crew size, led to new complex tasks.

The crew of 2 should include a driver and commander, who also acts as a system operator and gunner. At the same time, the load on the commander increases, which can reduce the combat effectiveness of the AFV. To solve this problem, various automation tools are required, which take on part of the commander's tasks.

Work on automation equipment continued until the close of the NGP program and produced some results. Subsequently, the development of this direction continued. In recent years, various versions of the AFV with a reduced crew and advanced electronics have been proposed again. However, so far, even on the newest models of German armored vehicles, the crew has been reduced to only three people: both the commander and the gunner-operator are still present in it.

Difficult and expensive future

The NGP program in its original form was developed until 1998, after which it was transformed with a change in tactical and technical requirements. In 2001, the second version of the program was closed for a variety of reasons. The overall complexity, cost, non-compliance with new requirements and other factors affected the fate of the program.

Special requirements were imposed on the NGP technique, the fulfillment of which was associated with noticeable difficulties. The search for solutions, technology development, etc. was required. which took time and money. Already in 1998The Bundeswehr came to the conclusion that it was impossible to simultaneously continue work on three platforms with the letters "A", "B" and "C". For this reason, the NGP program was cut by three times - to the development of the NeSPz armored personnel carrier.

The end of the NeSPz project is formally associated with the new NATO requirements that came out in 2001. They gave preference to air transportable equipment, and NGP and NeSPz fit into such requirements with great difficulty. However, this was not the only reason for abandoning the project. The armored personnel carrier needed further expensive development, which would take a lot of time, and its successful completion was not guaranteed.

Considering the course and results of the NGP program, it is easy to see that its participants have proposed, studied and, in some cases, implemented many new interesting solutions aimed at improving the characteristics of equipment. Some of these ideas turned out to be useful and found application in new projects. Others turned out to be overly complicated or unsuitable for practical use. Thus, the NGP program has produced some positive results - albeit indirectly. It is highly likely that her legacy will re-emerge in projects for the future.