- Author Matthew Elmers [email protected].

- Public 2023-12-16 21:49.

- Last modified 2025-01-24 09:17.

The Iveco MPV uses the latest IBD Deisenroth protection solutions, mainly based on nanotechnology

Passive Armor: The Last Barrier

The hulls of armored vehicles are still made of steel, to which additional armor kits are bolted. However, the more the basic design can give in terms of ballistic and explosive protection, the higher the final level of protection will be. In addition, even with the installation of active protection systems that destroy the attacking projectiles even on approach, the resulting high-energy fragments can cause serious damage to the vehicle, which again requires good basic protection

The Swedish company SSAB is one of the renowned specialists in the field of armor materials, and its Armox family of armor steels is well known throughout the world. The family includes six different types, the number in the designation of the steel grade indicates the average Brinell hardness. While hardness directly affects ballistic protection, toughness is needed to absorb blast energy - two characteristics that, in fact, cannot exist together. Formability exacerbates this contradiction, since high strength steels are generally less formable and often have problems with weldability.

Over time, the ballistic characteristics of SSAB steels gradually improved: in 1990, Armox 500T steel with a thickness of 9 mm was needed to stop the M193 / SS92 projectile flying at a speed of 937 m / s, but ten years later with the Armox 600T alloy, only 6 were needed to stop mm. Another ten years and 4.5mm Armox Advance does the same, although the number is no longer worth it, since the hardness is beyond the Brinell scale! From an initial 70.7 kg / m2, SSAB has managed to reduce weight to 47.1 kg / m2 in ten years, and down to 35.3 kg / m2 in the next decade. According to SSAB experts, no further significant decrease is expected, the real figure for 2020 is 30 kg / m2. The company's R&D department is working more on improving the toughness and formability of the existing material than on its hardness, especially since explosion is the main threat today. Its Armox 440T steel with 420-480 HB Brinell is dubbed the preferred energy eater, and its toughness makes it easy to get any shape, such as a solid bottom. Even the harder Armox 500T steel, with a hardness of 480-540 HB, is considered as a material for blast protection.

As mentioned above, the main characteristic of Armox Advanced is hardness, which is why this steel is considered by SSAB as a de facto ceramic. Therefore, the company strongly advises not to mold or weld it, since it should not be heated above 100 ° C to maintain its hardness. How to achieve similar levels of protection and weight in the future with more moldable materials is a very difficult task today.

Among the new armor steels, of course, it should be noted Super Bainite, introduced in the fall of 2011. Developed by the UK's DSTL Defense Science and Technology Laboratory, the new steel is manufactured at Tata Steel UK. It exhibits much better performance than standard armor steel. These characteristics are not only a consequence of the chemical composition, but also of the manufacturing process, in particular heat treatment with cooling with air and molten salts. The final product has twice the ballistic performance of rolled homogeneous armor.

South African company Aardvark Perroc uses SSAB Armox 500 steel extensively in its products. This demonstrates that even this high hardness steel is capable of absorbing large amounts of energy.

SSAB manufactures complex shapes from its Armox 440T steel, often referred to as an “energy eater”. It is very well suited for structures exposed to IEDs. SSAB is currently working to make its armor steels more moldable.

The use of IBD FlexiComp lining allows the production of volumetric security elements, reducing the number of weak points in the overall security system

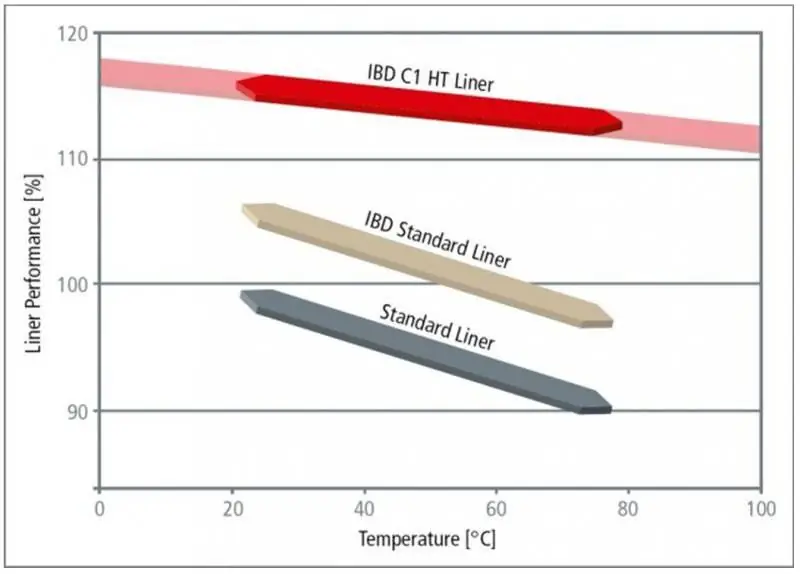

Diagram of the characteristics of IBD liners as a function of temperature. The effect of high temperatures is a major concern when deploying machines in hot climates

In December 2012, Lockheed Martin UK and the University of Surrey announced a new, simpler method to improve the protection and survivability of armored vehicles. Scientists have developed a method for treating ceramic materials in order to improve the adhesion strength of alumina ceramics and silicon carbide ceramics to a composite substrate, which significantly increases the strength of the armor. Attaching ceramic plates to their backing has always been the Achilles heel of this technology. The results showed that the new technique improves traction forces. Tests have shown that when a 14.5mm armor-piercing incendiary bullet is fired at an armor plate, it remains intact.

Technological development remains the core business of IBD Deisenroth Engineering, while passive solutions are currently outsourced to Rheinmetall Chempro, 51% owned by Rheinmetall Defense and 49% by the Deisenroth family.

When Dr. Ulf Deisenroth developed the fourth generation armor technologies for various types of materials, the task was to reduce mass while maintaining the level of protection, or vice versa, to increase the level of protection for a given mass, while new technologies promise savings of over 40%. They are based on the latest breakthroughs in the field of passive protection associated with nanomaterials, which include nanocrystalline ceramics, nanometric steel and high-strength fibers. In collaboration with steelmakers, IBD has developed high-strength Nitrogen steels that are nearly on par with standard ceramic materials. These new types of steels can be applied to structural elements, while they can achieve even greater weight savings if they are used in the early stages of design. As for high-strength fibers, for example, IBD C1 HT Liner, they have characteristics that are almost 20% higher not only compared to standard lining, but even 10% higher than other lining from IBD; the deterioration of their parameters with increasing temperatures is also slower, which is especially important given the extreme temperatures on modern battlefields. In addition to nanoscale steels and nanoceramics used on newly developed machines, IBD has also developed new composite material solutions that allow the production of elements with complex curved geometries, which makes it possible to achieve 100% coverage of the protected area with almost no ballistic gaps. This solution is used in particular in the production of bottom elements, where the slightest gap can compromise the entire protection.

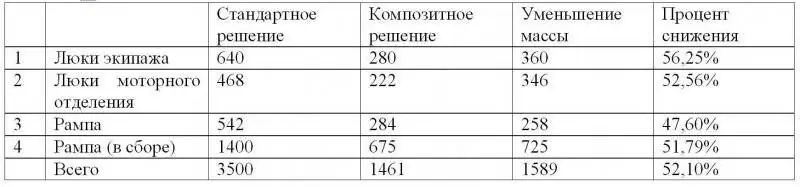

IBD has also been successful in the development of nanocomposite laminates that are so significantly increased in strength that they can replace structural parts of a machine while also serving as high-level ballistic protection. Due to their low surface density, the overall weight of this level of protection is thus significantly reduced. These composites are based on the aforementioned nanotechnology materials from IBD. Specific bonding processes have been developed and are used to make nanocomposite laminates of structural materials, known as IBD FlexiComp, with increased structural strength and ballistic performance. With a 10% lower density compared to standard laminates, the elastic properties of these materials are twice as high. This high strength allows them to be integrated into the design of the machine, while ballistic performance allows it to cope with high-level threats, while FlexiComp materials have good potential for weight reduction. Their use can be embodied in two different approaches. A direct approach is to use them for protection against mines and IEDs as additional armor in wheel arches, fenders, as mine plates and spaced internal floors. When molding volumetric parts, they can replace other solutions, such as assemblies assembled by welding or bolting. The second approach is the integration of composite parts such as hatches, engine hatches, aft doors and ramps. They make up a large proportion of the total surface of the vehicle, and as a result, the absolute reduction in mass will be very significant. For STANAG 4569 Level 4, this weight reduction is 1500 kg for an 8x8 machine (see table). In terms of manufacturing costs, the processes developed by IBD allow the production of composite parts without the use of autoclaves, providing significant cost savings, especially for large components, their cost is comparable to the cost of components produced using standard technologies.

These components are currently manufactured by Rheinmetall Chempro, whose task is to master IBD Deisenroth Engineering technologies, develop them into a production process in order to achieve competitive prices, further develop specialized solutions and follow them up to the machine qualification process. Deliveries of components made using the latest advanced technologies began in early 2013, primarily AMPV machines from KMW-Rheinmetall and Medium Protected Vehicle from Iveco DV-KMW. More than a dozen Original Equipment Manufacturers around the world will soon receive components that will enable them to truly reduce the weight of their machines, thereby increasing payload and lower lifecycle costs, Rheinmetall's Protection Division said.

Rheinmetall Chempro's passive portfolio includes various versions of the Amap (Advanced Modular Armor Protection) family. This family uses the latest technology developed by IBD. Amap products are typically combined to provide the desired protection against a wide variety of threats. Among the various opaque products, we see the Amap-B ballistic solution, which provides protection against small arms and medium-caliber ammunition, Amap-M mine protection, Amap-IED designed to combat IEDs, Amap-L liners that protect the fighting compartment by absorbing secondary shrapnel, Amap-SC against HEAT projectiles and, finally, the Amap-X solution, which protects against threats typical for urban conditions.

New bonding technology developed by Lockheed Martin UK and the University of Surrey could significantly improve the protection of armored vehicles such as the Warrior BMP (above)

Additional SidePro-ATR modules for MBT Leopard

It should be noted that within the Rheinmetall Group, another company is engaged in passive protection, Rheinmetall Ballistic Protection GmbH, which received its new name on January 1, 2013. Previously, it was called Rheinmetall Verseidag Ballistic Protection GmbH. Fully owned by Rheinmetall, this firm specializes in the design and manufacture of armouring solutions for light military vehicles that use materials such as ceramics, advanced metals and specialty fabrics.

Although Ruag Defense still has solutions for dynamic protection (active-reactive armor) in its portfolio, it no longer looks to consumers as an ultra-modern company capable of increasing the survivability of medium and heavy vehicles. In this regard, the Swiss company turned its attention to perfecting completely passive solutions that can cope with kinetic and shaped charges. The SidePro-ATR system goes far beyond the aggressiveness of the RPG-7, as it can handle the shaped charges used in symmetrical scenarios, while the base version guarantees Level 5 ballistic protection. SidePro-ATR was first shown to the public in 2012, this system is scalable and thus it can be used both on armored personnel carriers and on tanks. In its basic version, it has a thickness of 400 mm, and its mass is comparable to the mass of a reactive solution (that is, approximately 300 kg / m2). This system was qualified for the Leopard 2A4 tank. The level of ballistic protection can be significantly increased to the point that the system will withstand the impact of a 120-mm elongated core, although no data was provided in this regard.

The scalability of SidePro-ATR allows it to be used in symmetrical and asymmetric combat scenarios. Another solution to combat kinetic ammunition and IEDs under the designation SidePro-KE / IED was tested on the Fennek armored reconnaissance vehicle, which is in service with Germany and the Netherlands. Mainly based on ceramics, this solution was intended to combat first generation IEDs. New roadside bombs, used in various theaters, generate thousands of high-velocity fragments, and therefore there is a need for very good multi-impact characteristics. Since then, Ruag has refined the KE / IED system, moving away from ceramics and using non-expandable multilayer bags. The new SidePro-KE / IED solution, available since 2012, offers Level 4 / Level 5 protection against kinetic weapons and has extremely high multi-impact performance. Assuming the chassis is made of 7mm ballistic steel, a 30mm panel could provide the full protection required, with the KE / IED system allowing for the smallest weight gain depending only on the vehicle type. This solution is pending with several manufacturers.

Ruag has finalized the SidePro KE / IED. The photomontage shows the elements of a system designed to counter new devices that generate multiple fragments.

BTR M113, equipped with a passive anti-RPG system Iron Wall from Israel Military Industries, combining passive and lattice armor

Ceradyne and Cellular Materials International have developed a bottom shield based on CMI MicroTruss aluminum honeycomb that absorbs up to a third of the energy generated by an explosion. Below is the close-up of the MicroTruss material.

Example of weight reduction for an 8 x 8 machine with components made from IBD FLEXICOMP

Weight in kg

Plasan Sasa remains one of the key players in the passive booking industry. No technological details are given in this area, while the company is active both in additional bookings and in prefabricated buildings. The second approach was taken with the development of the Mrap from Navistar MaxxPro and the M-ATV from Oshkosh. “This allows us to increase production using a workforce without welding skills, as our Lego-style approach is based on blocks containing all the components that can be assembled in a minimum of time,” a company source said. Some of the more than two hundred engineers of the company are working on new solutions that could result from the emergence of new materials or innovative geometric solutions. The systems approach remains at the heart of the protection cycle.

IMI has recently developed a range of passive and reactive solutions to counter the latest types of IEDs, including the various types of EFP or SFF (Self Formed Fragmentation) "shock cores" and the latest RPG models. The company has proposed a passive Iron Wall solution based on a combination of metal and composites supplemented with lattice armor. Depending on the level of protection required, the thickness can vary between 110 and 150 mm and the weight between 200 and 230 kg / m2. Iron Wall is currently undergoing military trials with the Israeli army.

IMI also offers its lattice armor as a standalone system. L-VAS (Light Vehicle Armor System - armoring system for light vehicles) is designed to protect vehicles such as armored personnel carriers. In order to reduce weight, the system is based on composite materials and reactive elements, the latter contain a minimum of energetic materials. This reduces indirect losses, and the type of material avoids the risk of secondary detonation of adjacent elements. According to IMI, the L-VAS system also protects against 14.5mm armor-piercing rounds and artillery fragments. The system has been fully qualified in Israel for its M113 APC and has a specific gravity of approximately 200 kg / m2.

A heavier Breakwater system is also offered. This reactive armor, comprising metal and composite elements, is designed to combat three main threats: RPG, SFF and EFP. IMI has carried out extensive testing and is currently proceeding with qualifications to begin production of a solution with a thickness of 350 - 400 mm and a weight of 430 - 450 kg / m2 at the end of 2013.

Ceradyne is another major player in passive booking. According to Mark King, president of Ceradyne, steel remains the main material in the booking business, with the goal of improving performance and reducing cost. “In the United States, the driving factor is mainly the cost of acquiring a vehicle, not the cost of its lifespan, and this works against upgrades,” King said at the 2012 AUSA conference. while in the United States, the emphasis was on quantity, which brought European developers of protection systems ahead of American ones. However, King stressed that America is currently progressing, mainly focusing on anti-explosive underbody protection, since ballistic protection is seen as a solved problem. The interest of the American army, again shown in solving the problem of protecting the bottom of such machines as, for example, the Humvee ($ 20 million only for development), is positively assessed by King. Ceradyne is one of those who will definitely compete for a contract for their modernization. The requirement provides for maximum protection with significant weight savings in order to reduce the impact on machine performance.

Ceradyne has developed a MicroTruss solution from Cellular Materials International Inc (CMI). This porous aluminum alloy material has a density of 58 kg / m2 compared to the density of 112 kg / m2 of an equivalent monolithic metal solution. This solution differs in the "V" angle of the body equal to only 5 °, which is sufficient to reflect the blast wave and has a mass of 300 kg. MicroTruss guarantees absorption of up to 30% of the explosion energy, which not only limits the impact on the crew capsule, but also reduces the vertical movement of the vehicle. Ceradyne is also heavily involved in the Flyer Gen.2 reservation program, which is targeting the Special Operations Forces project for the GMV 1.1. To maintain transportability inside V-22, CH-47D and CH-53E helicopters when mass and width must be kept within certain limits, the company has developed a kit that provides a B6 (.357 Magnum) level of ballistic protection for the doors and roof.

Polaris Defense and M9 Defense Armor Technology have developed a hybrid steel composite structural armor that can significantly reduce the Humvee's own weight while maintaining protection levels. The prototype pictured on the right has a curb weight of only 3400 kg, which is almost 50% less than the Humvee with Level 3 protection.(Note the wheels of the car at the bottom)

Protection is also about not being left on the battlefield in the event of a punctured wheel. Non-pneumatic wheels from Polaris Defense guarantee significantly better durability compared to standard tires and can withstand a 12.7mm bullet. Currently, they are available not only for cars, including the Hummer class, but now these wheels are also being developed for the heavier Mraps class cars.

Ceradyne is also participating in the Marines Personnel Carrier program in partnership with Lockheed Martin and Patria on a Marine Corps vehicle based on the Finnish Patria AMV. It is worth noting that on November 28, 2012, it was announced that Ceradyne was acquired by the 3M Group, which will allow it to invest more in R&D and innovative solutions.

Integration of design and protection is a highly sought after solution for light vehicles. At AUSA 2012, Polaris Defense unveiled a prototype Humvee vehicle with a new concept it developed in collaboration with M9 Defense. The challenge is to reduce curb weight while maintaining and increasing protection levels. To do this, the Polaris-M9 team removed all of the overhead armor to take a look at the structural armor concept. Then everything was removed from the car, only the bare chassis was left, and then a lightweight hybrid (steel-composite material) structure was put on it. This structural armor can provide Level 3 protection with a mass of 70 kg / m2, and with a mass of 83 kg / m2, it is capable of withstanding a 12.7 x 99 mm bullet, although the Polaris-M9 group is confident that they can reach Level 3+ (12, 7 mm armor-piercing bullet). The Polaris-M9 solution also protects the engine. While a standard Hummer armored vehicle weighs approximately 6,350 kg, the proposed solution allows its weight to be reduced to 3400 kg. The hybrid structural armor uses a non-exotic material, which allows the Polaris-M9 team to talk about the cost of the new solution, comparable to the cost of the current solutions. In addition, this material is molded into complex shapes, resulting in, among other things, seamless V-shaped bottoms. Achieving the desired shape is achieved through hydraulic forming - a high-speed process that helps to reduce costs. According to the Polaris-M9 team, this technology can reduce weight by 40 percent.

Demonstration of non-pneumatic wheels from Polaris Defense

Another term directly related to mobility is included in the defense equation - the wheel. Following the acquisition of Resilient Technologies, Polaris Defense is now offering Non-Pneumatic Wheels (NPT). Wheel consumption is one of the most important logistical problems in a turbine engine and the NPT solution will in many cases help to solve it. According to the command of special operations forces in Afghanistan, conventional tires travel approximately 1,300 km, while an NPT wheel punctured by a 12.7 mm bullet can travel more than 8,000 km and, therefore, displace spare wheels from the supply chain, while improving ride quality. NPT prototypes have already been made for Hummer vehicles. The current target is a set of NPT wheels for the 7.7 ton machine, which is almost the total weight of the JLTV General Purpose variant. According to company representatives, modeling showed that the mass can reach 18 tons, in other words, the wheels can withstand a Mrap class car. As the payload increases, the technology remains the same, and the company's simulation programs allow very accurate predictions. What will change is the material that has to adapt to the mass, which in turn has yet to appear in the future.