- Author Matthew Elmers elmers@military-review.com.

- Public 2023-12-16 21:49.

- Last modified 2025-01-24 09:17.

German approach

In the first part of the material on welding technologies during the Great Patriotic War, it was mentioned that one of the main achievements of Soviet technologists and scientists was the introduction of automation of welding of tank hulls and towers. In Nazi Germany, automatic welding was not used in tank factories. There was one very important explanation for this - during the main period of the war, the tank industry of the Third Reich did not experience a shortage of highly qualified labor, including welders. And in the Soviet Union, during the evacuation of large enterprises to the east, personnel valuable for the industry were lost, which jeopardized not only the quality of tank assembly, but even the very possibility of production. In Germany, it came to the point that when welding the hulls of "Panthers" and "Tigers" individual welders were assigned to separate seams! Engineer V. V. Ardentov writes about this in the material "German experience in cutting armor and welding of tank hulls" in the "Bulletin of the tank industry" in the victorious 1945 year. His work was based on the study of two armored hull factories in Kirchmeser and Brandenburg. Obviously, these factories could afford such technological luxury in the form of separate welders for separate seams until the last months of the war.

Before welding the hulls, the armor plates were cut, which until 1942 was carried out mechanically. For cutting out armor plates for thorn-to-thorn connections, it was much more convenient to use acetylene-oxygen cutting, which was also used in similar situations in the Soviet tank industry. Here the Germans were ahead of our tank builders both in efficiency and in quality of the cut. This is largely the result of the use of high-quality tools (gas-cutting machines Messer and Grisheim) with the ability to fine-tune the thickness of the armor plate. Also, the Germans used oxygen of a high degree of purification - more than 99%. Finally, in the course of cutting the armor, the Germans used several torches, including for chamfering. The flame cutting process itself was automated - this made it possible to speed up the process and make it much more accurate.

[center]

[/center]

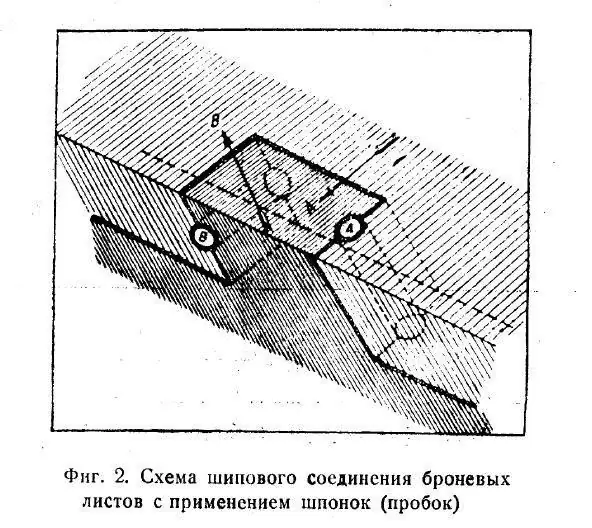

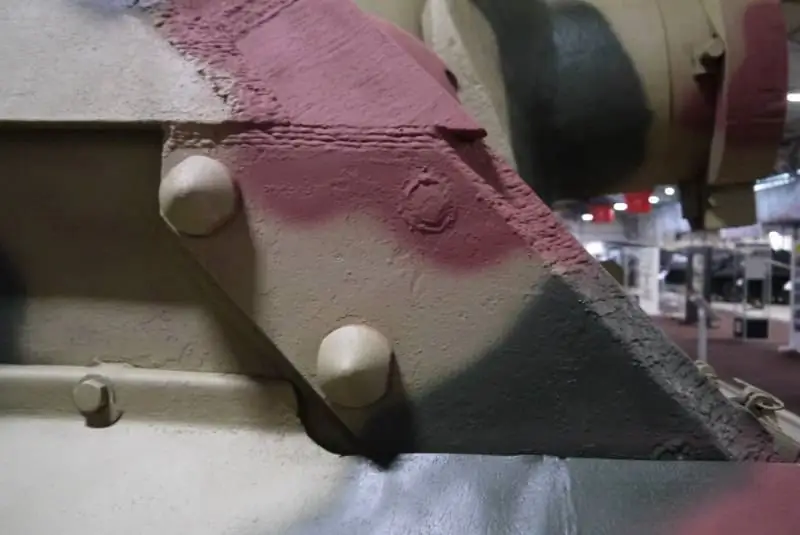

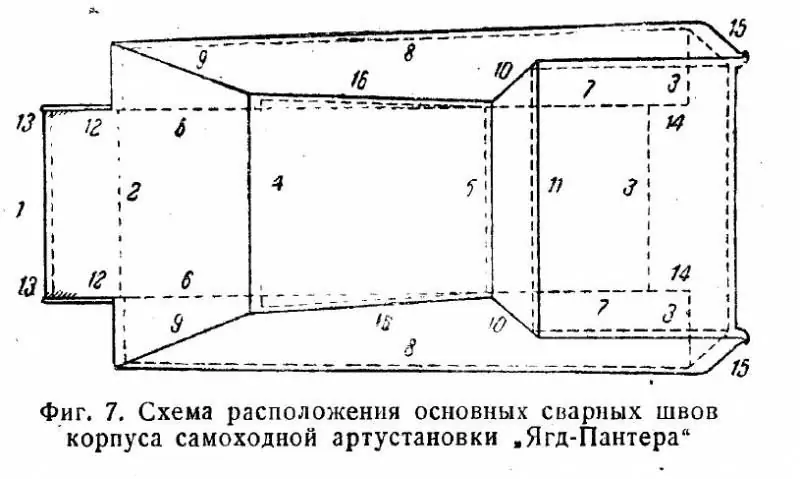

As you know, one of the distinguishing features of the hulls of German tanks from 1942 was the spike connection of armor plates with a rectangular or oblique spike. At the same time, the Germans were not limited to a simple articulation - in addition, for strength, cylindrical keys or plugs were introduced into the joints. In particular, this was common on medium tanks "Panther", self-propelled guns "Ferdinand", towers of heavy "Tigers" and a few corps of "Maus". Such plugs were steel rolls up to 80 mm in diameter inserted into the joints of the sheets to be joined after being assembled for welding. The plugs were placed in the plane of the edges of the spike of the armor plates - a pair of them was required for each joint. In fact, after the installation of the keys, the spike connection became one-piece even before welding. In this case, the dowels were mounted flush with the surface with the armor and welded along the perimeter of the base. The spike connection of the armor plates of the tank hulls markedly improved the ballistic protection of both welds and armor. First of all, this was ensured by increasing the total length of the weld, consisting of separate segments, which somewhat reduced the propagation of cracks.

One of the problems in the manufacture of the hulls of German tanks was the manufacture of cutouts and holes (for example, for the armor joints mentioned above). It was impossible to cut them with gas, so drilling was used. Initially, for steels of grades E-18 and E-19, which underwent the surface hardening procedure, it was generally impossible to find a suitable drill, the outer layer of the armor turned out to be so hard. In the case of drilling a hole before quenching, an uneven quenching was formed in the area of the hole, followed by deformation and radial cracking. Yes, there were cracks on the German tanks, and not small ones, and the German efforts to avoid them will be discussed later. Partly, the problem of uneven hardening of the armor in the area of the holes was solved by a special refractory paste, which was used to cover the holes before being sent to the furnace. But, again, this only partially solved the problem. It was only at the end of 1944 at the Electrothermal Institute in Essen that this problem was solved by a local tempering procedure on the hardened area of the armor. The unit, developed by the Germans, is described in his article by the winner of the Stalin Prize, Candidate of Technical Sciences A. A. Shmykov. The material was published in the specialized edition “Bulletin of Tank Industry”, which was secret for its time and familiar to us, at the end of 1945. In the post-war years, the pages of the Vestnik were rich in detailed analysis of the engineering tricks of German engineers, since there were enough captured equipment.

But back to the local release of the armor where the holes were drilled. The basis of the unit was a graphite electrode connected to the drilling site, through which an electric current of 220 amperes and a voltage of 380 volts was passed. As a result, the armor was heated to the tempering temperature. Depending on the thickness of the armor and the diameter of the hole, this took from 7 to 15 minutes. After the tempering procedure, the hardness of the armor decreased 2-2.5 times. It is noteworthy that the domestic industry (including the tank industry) also used steel tempering by heating by current - the "know-how" of the Germans was only in the use of a graphite electrode.

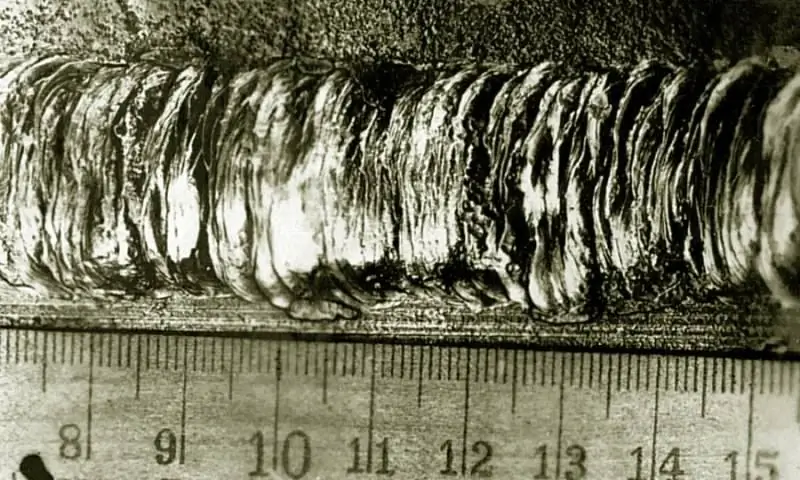

Germans and electrodes

The Germans also used vacation when welding sheets of their high-hardness armor with a carbon content in the range of 0.40-0.48%. This became known to the specialists of TsNII-48 (Armored Institute) during the war, when metallurgical engineers were looking for recipes to reduce cracking in the T-34 armor. As it turned out, the Germans released the armor plates at temperatures of 500-600 degrees (high vacation), and then welded the armor preheated to 150-200 degrees in several passes. Welders did not use electrodes with a diameter of more than 5 mm - hard to believe, given the thickness of the armor of German tanks. Electrodes with a diameter of 4 mm worked at a current of 120-140 amperes, with a diameter of 5-6 mm - 140-160 amperes. This technology made it possible not to overheat the weld area. This means that a smaller quenching and tempering zone was obtained. In addition, after welding, the seam cooled very slowly - all this eventually allowed the Germans to more or less successfully deal with cracks in the places of welded joints. In addition, austenitic electrodes were predominantly used, which led to a high ductility of the weld and its prolonged transition to a brittle martensitic state. Engineers of TsNII-48 very carefully studied the features of the technological cycle of welding tank armor, which made it possible to successfully transfer these techniques to the production cycle of the T-34. Naturally, no one in the tank industry could afford such a painstaking multi-layer application of welding seams throughout the tank hull, German "know-how" was used only in the most critical seams prone to cracking.

The Germans carried out welding of tank hulls in fairly comfortable conditions on huge tilters without preliminary tacks (although in some cases they still passed a 5-mm electrode along the entire length of the joint). The tilter was a structure on which, like on a spit, the carcass of a German tank rotated around the longitudinal axis. The drive was either manual or electric. Due to the high cutting accuracy, the gaps between the parts of the body assembled on the rotator did not exceed (at least in the main period of the war) 3-4 mm. Otherwise, steel process gaskets were used. Long seams were broken by welders into several small ones and welded simultaneously in one direction. The closing seams were also welded by two welders synchronously towards each other. This ensured the minimum hardening stress of the steel and the most uniform distribution. According to one of the legends, voiced by Alexander Volgin in the material "Frame for the German Menagerie", the salary of welders at some enterprises of the Third Reich was piecework - for the mass of metal deposited on the tank.

There is no need to talk about any special rules for the control of welding seams in the German tank industry - there was no X-ray, no magnetic flaw detection, no primitive drilling. And there were cracks in the seams! If they were up to 100 mm long, then they were ground and welded, and if more, then they were melted with an electric arc and also welded. They also did the same with visually detected cracks in the main armor. By the way, over time, the Germans managed to reduce the proportion of cracks in welded seams from 30-40% to 10-20% due to new compositions of electrodes. Also used was the alternation of passes in multilayer welds with austenitic and ferrite electrodes.