- Author Matthew Elmers elmers@military-review.com.

- Public 2023-12-16 21:49.

- Last modified 2025-01-24 09:17.

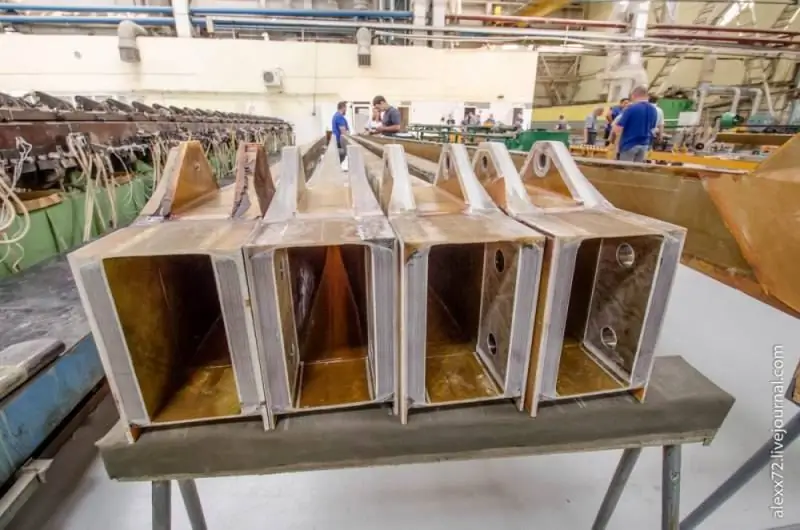

Such a heavy machine as the Mi-26 must be lifted into the air by a propeller of a classical design, which will ensure its reliability and durability. At the time of development, Mil Design Bureau had very little experience in creating fiberglass blades, so at first it was decided to abandon them in the new transport helicopter. Steel was chosen as the material of the propeller spars, which provided a large margin of fatigue strength. There was also know-how - the lugs for fastening to the bushing were made in one piece with the main pipe of the screw, which made it possible to strengthen the structure without increasing the mass. Fiberglass still found its place in the blade as a form-building structure around the steel spar.

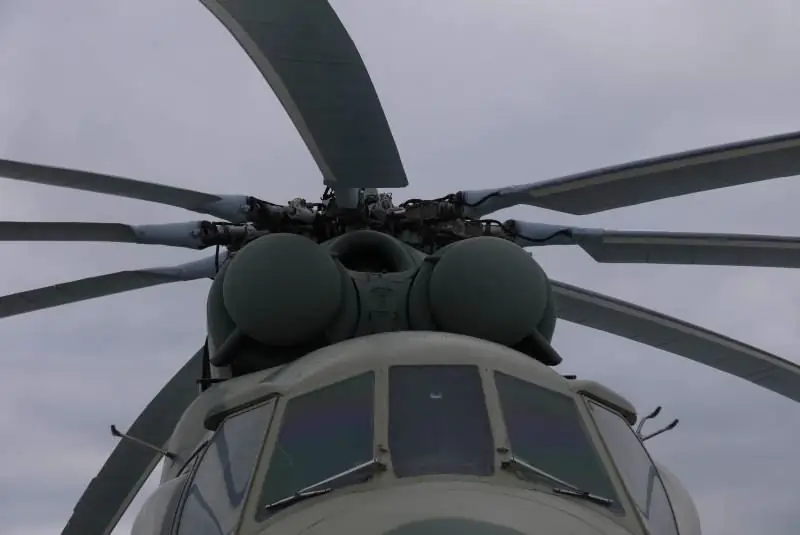

Mi-26 in the exposition of the Patriot park

The manual laying of the fiberglass shell of the blade resulted in the formation of folds, which could lead to the formation of cracks later in operation. For this reason, it was necessary to install a pneumatic system for detecting through cracks in the propeller blades. The uniqueness of the Mi-26 main rotor was added by its eight blades, which was the first such experience in the world helicopter industry. It was not possible to lift such a heavy machine into the air with another screw. The assembly of such a massive screw required the installation of removable sleeve sleeves, and a separate torsion bar was designed for the sleeve to level the centrifugal force. In general, the bushing turned out to be extremely innovative - many of the hinges were made with metal-fluoroplastic bearings, and in the design the steel was replaced with titanium. The progress made by the KB engineers in designing the main rotor for the Mi-26 is noteworthy. Compared to a five-bladed propeller with a diameter of 35 meters in the Mi-6, the eight-bladed 28-meter propeller in the Mi-26 developed 30% more thrust, while its mass was 40% less.

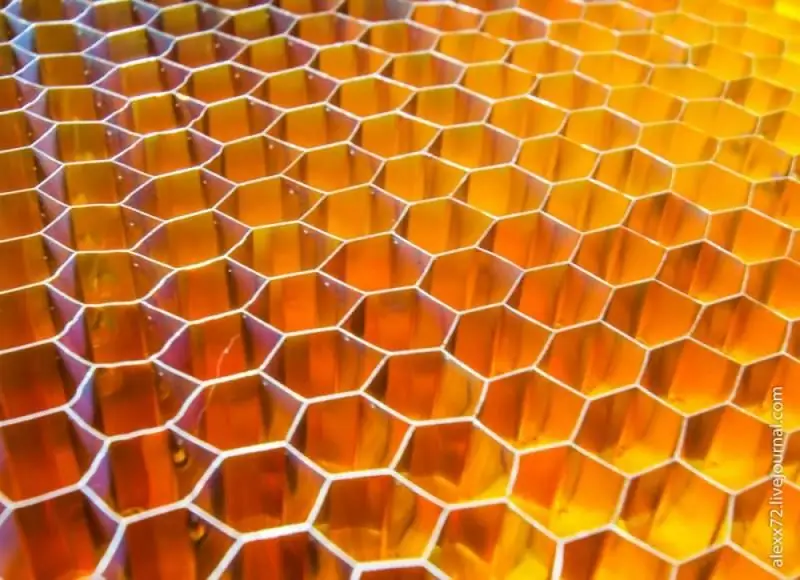

By 1977, the propeller was finally tested both at TsAGI and at the Mi-6 flying laboratory. The conclusions were unambiguous: the design fully meets the requirements of the new helicopter and can be recommended for serial production. If the engineers were afraid of creating a power frame made of fiberglass with the main rotor, then they decided not to be careful with the steering rotor - it was completely made of material that was new for that time. This made it possible to significantly save on the weight of the finished product. The manual laying of the fiberglass shell of the main rotor already in the 60s looked like an anachronism, and on the initiative of Mikhail Leontyevich Mil, the design bureau began to develop machine winding of the shells. Then the idea of a fixed mandrel was born, around which a winding device with four spreaders rotates. The winding itself on the spar is carried out with a prepared prepreg tape, and the process is controlled by a complex CNC machine. Milevtsy attracted NIAT specialists to the development, who helped to create a mathematical model of winding the shell on mandrels of a complex shape - the rotor blades. The program received the nontrivial name "Winding". There were a lot of bonuses from the new method of manufacturing the main rotor shell: the blade surface became homogeneous, lost seams, which, in comparison with its predecessors, led to greater durability and survivability.

The modern process of manufacturing rotor blades for machines of the Mil family at the Rostvertol enterprise (Rostov-on-Don)

The next engineering masterpiece of the Mi-26 is the main gearbox VR-26, which still remains unsurpassed in the world in terms of the power transmitted to the rotor. Not a single engine design bureau at that time in the USSR was able to create a gearbox of the required parameters, so Mil Design Bureau had to develop the unit on its own. Engineers were immediately faced with the choice of the gearbox kinematics scheme - the traditional planetary one competed with the innovative multi-threaded one. The latter was not previously used in the domestic industry, and there was no experience of its long-term operation. However, the significant weight gain of the new design has tipped the scales in favor of a multi-threaded design. If we compare the VR-26 gearbox with the early R-7, which is installed on the Mi-6, then the new product is only 8.5% heavier than its predecessor, but it transmits 1.5 times more torque (the transmitted power has doubled at once) …

[/center]

Main gearbox VR-26 and manufacturing company (Perm)

Summing up the design features of the Mi-26, it should be said that the vehicle has a high basing autonomy. It is weakly dependent on the airfield infrastructure - there is no longer the need for stepladders, ladders and similar equipment. The helicopter is equipped with hinged hoods and power plant panels that can be operated by service personnel. Inside the giant tail boom and keel, there is a passage to the tail rotor. The fuselage of the vehicle is replete with ladders, manholes and hatches, which greatly simplifies ground handling.

[center]

Gurgen Rubenovich Karapetyan, test pilot, Hero of the Soviet Union

The final appearance and design of the Mi-26 was formed by 1975, which made it possible to start assembling prototypes. Only by December 1977, the firstborn rolled out of the gates of an assembly plant in Panki near Moscow. And on December 14, the crew of test pilot Gurgen Rubenovich Karapetyan lifted the giant for the first time into the air. In February 1978, in Lyubertsy, they began full-fledged factory tests, which were developing very well - by 1979, the first copy of the Mi-26 had already been submitted for state tests. At the same time, the Rostov Helicopter Plant was already taking the first steps towards putting the machine into serial production. The tests revealed the first and only serious flaw - in some operating modes, transverse low-frequency vibrations appeared. Analysis has shown that the reason is the imperfect shape of the cowl fairings. Engineers quickly made adjustments and, at the same time, replaced the rotor blades with new ones with improved aerodynamics.

Future giants on the stocks in Rostov-on-Don

By May 1979, the second copy of the Mi-26 was connected to the tests, on which the transport capabilities of the helicopter were tested. A year and a half later, the giant performed a trick that no one had done before - he landed on autorotation with a total mass of more than 50 tons. During the tests, the car made 12 landings in autorotation mode and with the engines turned off. Much later, in 1997, the Mi-26 in a test flight landed on autorotation with a flight weight of 56 tons! In the course of work, the Soviet rotary-wing giant developed its own method of transferring the machine to a safe autorotation mode. For this, the pilot had to create a certain pitch angle, which translates the car into pitch-up with a simultaneous decrease in the overall pitch of the main rotor. Only according to this scheme, the main rotor had time to spin up to the speed required for landing. The vertical landing speed in this case was 2.5 m / s. In total, in the second phase of state tests (stage "B"), the experienced helicopter flew 104 hours and made 150 flights. It is noteworthy that the first prototype of the Mi-26 is still in service and works with a test vehicle at the Mil Moscow Helicopter Plant.

Roll-out of the first prototype Mi-26 from the assembly plant to the flight test station of the Moscow Helicopter Plant in Panki

On August 26, 1980, in the final act of state tests, it was written: “The Mi-26 experimental medium military transport helicopter passed the state joint tests on stage“B”… Flight technical, combat and operational characteristics basically correspond to the characteristics specified by the decree. The static ceiling and maximum loads exceed those specified by the TTT … An experienced military transport helicopter Mi-26 and its components, which received a positive assessment according to the test results, should be recommended for launch into serial production and adopted by the Soviet Army. " Note that in the army, according to the classification, it was considered "average". Obviously, the military was comparing the Mi-26 with the even more monstrous B-12.